Metallurigical Analysis of Third to Fifth Century Swords with Ring Pommels Excavated in the Asan-Cheonan Region

Article information

Abstract

This study conducts a metallurgical analysis of three swords with ring pommels (Hwandu sword) manufactured during the Proto–Three Kingdoms period and the Baekje period and excavated from the Asan and Cheonan. Specifically, we carried out analyses based on a metallurgical microscope, scanning electron microscopy with energy dispersive spectroscopy. the swords were made of bloomery iron produced through direct smelting and formed by hammering hypoeutectoid steel. It was also confirmed that other heat treatment techniques than shaping were not applied to them. In addition, all of them have a high carbon content and the crystal grains are well refined, so it is believed that the hardness and strength are high. Moreover, the analytic results of nonmetallic inclusions, No.2 swords have glassy slag and the others verified the existence of fayalite and wüstite on the glassy matrix. And a high Ca content overall. The results of comparing the swords with other swords with ring pommels excavated from the corresponding region indicated that heat treatment techniques were not applied to these artifacts despite the existence of such techniques. Thus, we analyze that the study subjects were produced as ceremonial items rather than weapons. Furthermore, the calculation results of ratios, such as CaO/SiO2 and (Al2O3/SiO2)/(CaO/SiO2), indicate that the study subjects were produced based on a similar smelting processing system. Based on the analytic results, this study also suggests a possibility of the addition of slag generation agents or the use of iron ores with a high Ca content.

1. INTRODUCTION

It is presumed that the Asan region was under the influence of Mahan before the establishment of Baekje and that Mahan’s Mokji state was located in the Cheonan region. These presumptions suggest that the Cheonan region served as a crucial hub during the Samhan period (Haneol Research Institute of Cultural Heritage, 2021).

Weaponry remains excavated from the Mahan and Baekje sites predominantly consist of three types: iron swords, spearheads and arrowheads. These weapons maintained a consistent presence from the third to the fifth century (Cho et al., 2014). Swords with ring pommels or Hwandu-do refer to swords with a round, ring-shaped handle head (Koo, 2004). Swords with ring pommels were used as weapons, prestige goods for representing the power of possessors, or symbolic tools for indicating social relationships to reinforce the royal authority of ancient states from the Proto–Three Kingdoms period to the Three Kingdoms Period of Korea.

Among different types of swords with ring pommels, swords with an undecorated ring pommels (so-hwandudo) refer to swords without additional decorations in the internal part of their external rings. Researchers suppose that these remains, being the most abundant and produced over an extended period, served as the foundation for the crafting of Decorated swords with ring pommels (Lee et al., 2009).

Information on the production of swords with an undecorated ring pommels can be obtained the most effectively through an analysis of archaeological properties depending on types, such as numbers and features. However, this analytic approach leads to limitations in identifying techniques applied to their production (Cho et al., 2020). Thus, this study conducted a metallurgical analysis of remaining microstructures and nonmetallic inclusions in iron remains to identify techniques applied to produce these artifacts in the entire process from smelting to processing.

The target iron artifacts were three swords with ring pommels manufactured during the Proto–Three Kingdoms and Baekje period and excavated from the Asan and Cheonan regions. Furthermore, this study compared them with swords with ring pommels examined in existing studies to characteristics in techniques applied to produce swords with ring pommels in the corresponding regions.

2. SAMPLES AND METHODS

2.1. Samples for analysis

This study are three swords with an undecorated ring pommels excavated from three historical sites. Information on the research targets can be briefly described as follows (Table 1).

The archaeological sites of Cheongdang-dong · Guryong-dong in Cheonan are located in Dongnam-gu, Cheonan, Chungcheongnam-do. Remains from the B site, where two of the research targets were excavated, were investigated, including the following: a pit-tombs (togwang-myo) and a pit-tomb with a surrounding ditch (jugu-togwang-myo) built during the Proto–Three Kingdoms period, a pit-tomb built after the Goryeo period, a residential house built after the Joseon period, and two storage pits (suhyeol-yugu) from an unidentified era. Moreover, grave goods including clamp, iron spears, iron sickles, deep-bowl-type potteries and swords with ring pommels, were excavated (Haneol Research Institute of Cultural Heritage, 2021). Among these remains, a sword with ring pommel excavated from the No.1 pit-tomb with a surrounding ditch built during the Proto–Three Kingdoms period and a sword with ring pommel excavated from a pit-tomb built during the Proto–Three Kingdoms period were selected as research subjects for this study.

The archaeological site of Galsan-ri in Asan is located in the area of 437-7, Galsan-ri, Tangjeong-myeon, Asan, Chungcheongnam-do. 348 remains from this site were investigated, including the following: two residential houses built during the Bronze Age, two pit-tombs with a surrounding ditch and 20 pit-tombs built during the Three Kingdoms Period of Korea, stone chamber tombs, and residential houses built during the Unified Silla period, and stone chamber tombs, pit-tombs, and residential houses built from the Goryeo period to the Joseon period. Moreover, large jars, iron axes, iron sickles, iron knives, swords with ring pommels, etc. were excavated (Haneol Research Institute of Cultural Heritage, 2022). Among these remains, a sword with ring pommels excavated from a pit-tomb built during the Three Kingdoms (Baekje) Period of Korea was selected as a research subject for this study.

2.2. Analysis methods

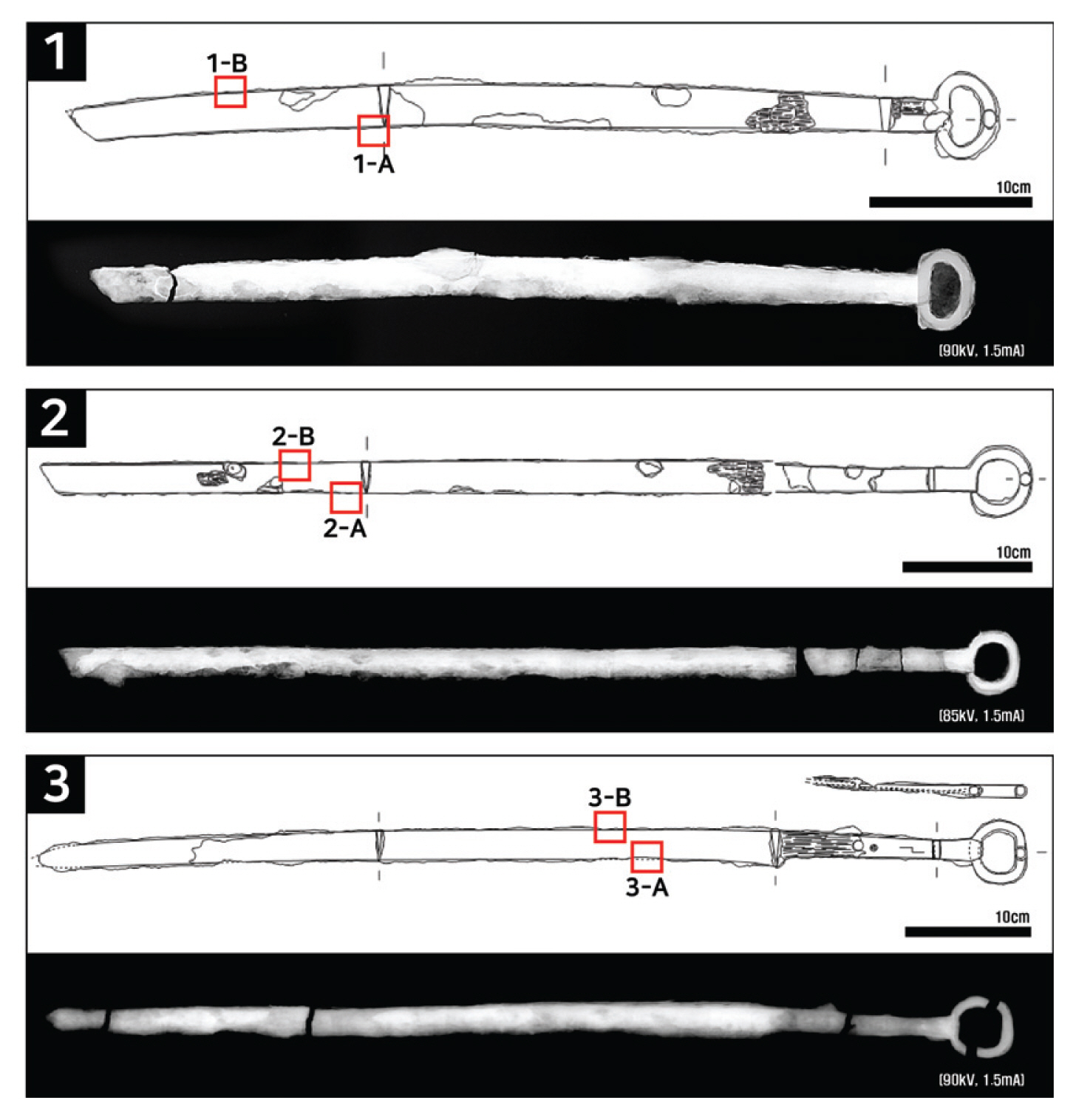

Prior to conducting an analysis, we reviewed excavation reports to obtain information on the location of excavation, forms of tombs, central age of remains, and other relevant details. We also carried out X-ray imaging (M-150, Softex, Japan) to identify techniques applied to produce ring pommels and hilts. The surveyed maps of remains included in this study are excerpts from excavation reports related to the corresponding remains, which were published by the Haneol Research Institute of Cultural Heritage in 2021 and 2022. On these surveyed maps, the locations of the samples collected are additionally indicated (Figure 1).

The metal cores of the research targets were observed based on their images obtained through X-ray imaging (M-150, Softex, Japan) to examine their microstructures, and a diamond Wheel was used to collect samples of these metal cores in a range of minimizing damage to the research targets. Samples were obtained from the blade (A) and back (B) sides of each research target, mounted using epoxy resins, and polished using sandpaper sheets in grits from 100 to 4,000.

Then, polishing clothes (MD-MOL, MD-NAP, Struers) and polishing agents (DP-Suspension P;3 μm, 1 μm, 0.1 μm; Struers) were used to apply fine polishing to the samples. The surfaces of samples obtained through the polishing process were etched using a 3% Nital solution (HNO3 3% + Ethyl Alcohol 97%).

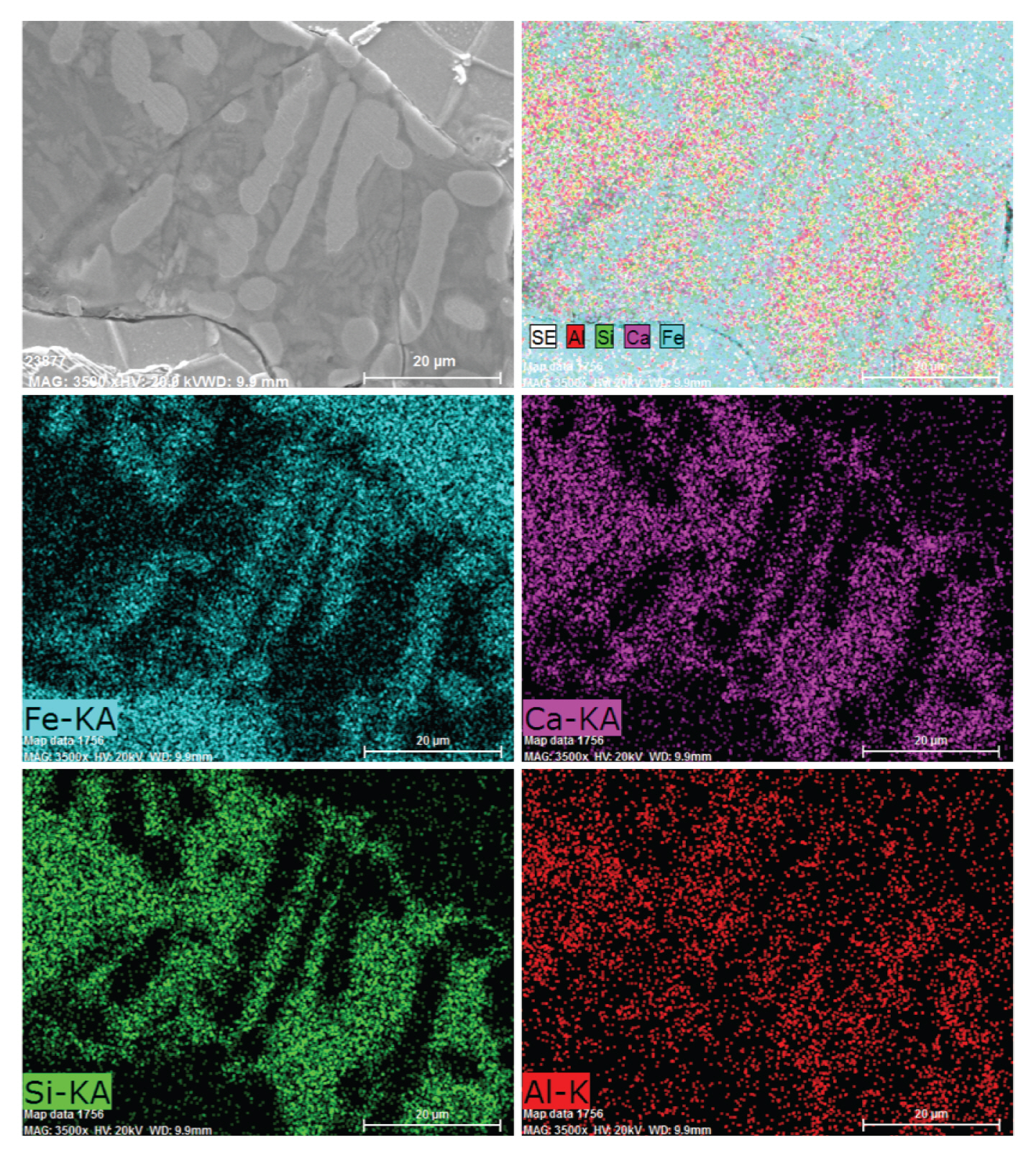

The etched samples were observed for microstructure and non-metallic inclusions under a metallurgical microscope (DM 2500 M, Leica, DEU). The entire structures were observed at 50 x magnification, with specific points further investigated at 100 x, 200 x, or 500 x magnification. The chemical composition of nonmetallic inclusions in the microstructure was observed using a scanning electron microscope (SEM, MIRA3, Tescan, CZE) and analyzed using an energy dispersive spectrometer (energy dispersive spectroscopy (EDS), QUANTAX200, Bruker, DEU) attached to the microscope. Additionally, EDS mapping was carried out to investigate the distribution of elements of nonmetallic inclusions in the microstructures.

3. ANALYTIC RESULTS

3.1. The archaeological sites of Cheongdangdong · Guryong-dong in Cheonan

3.1.1. A sword with a ring pommel excavated from a ditch-pit-tomb during the Proto–Three Kingdoms period (No. 1)

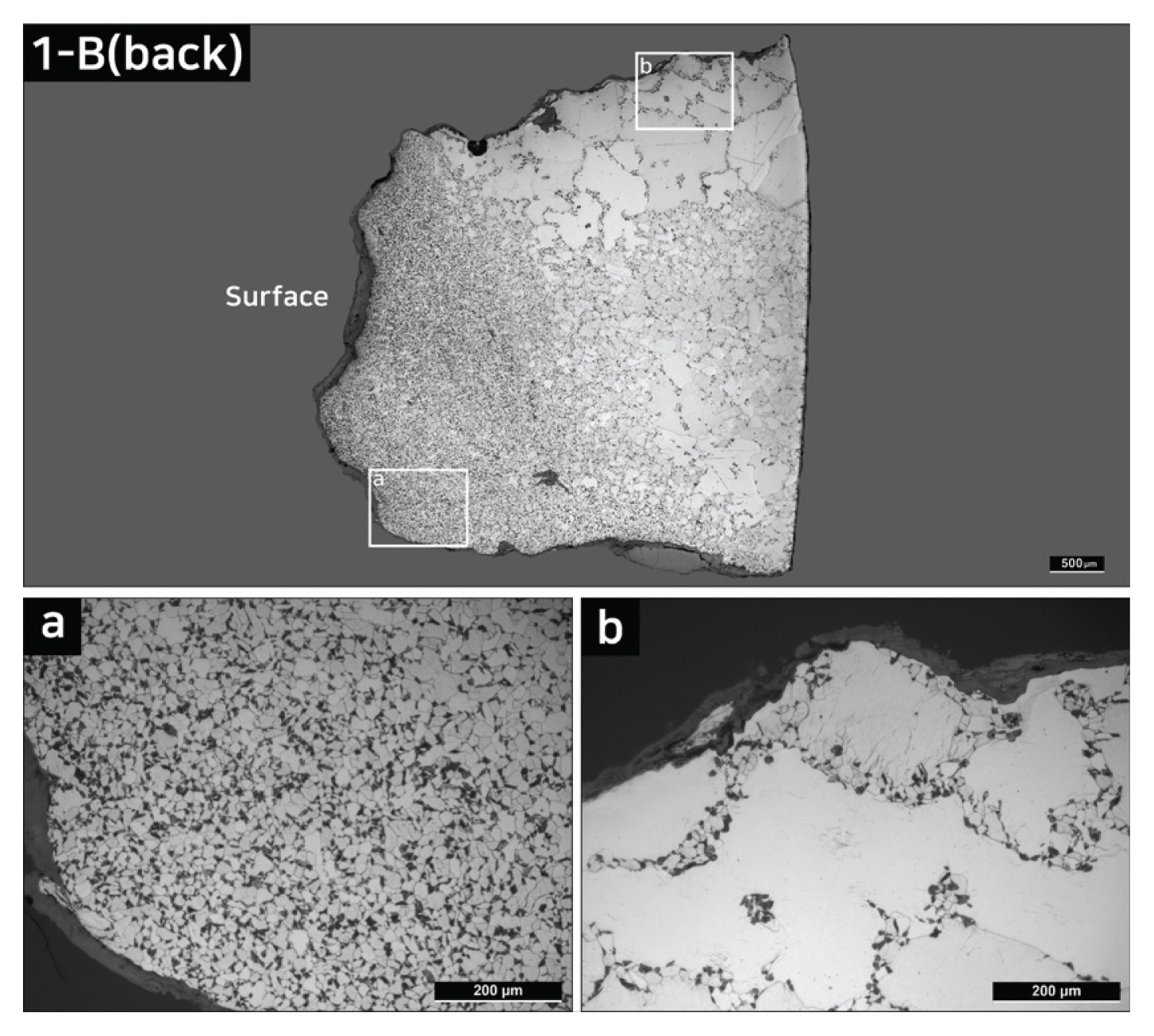

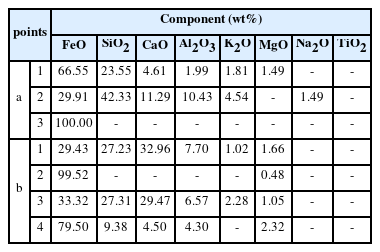

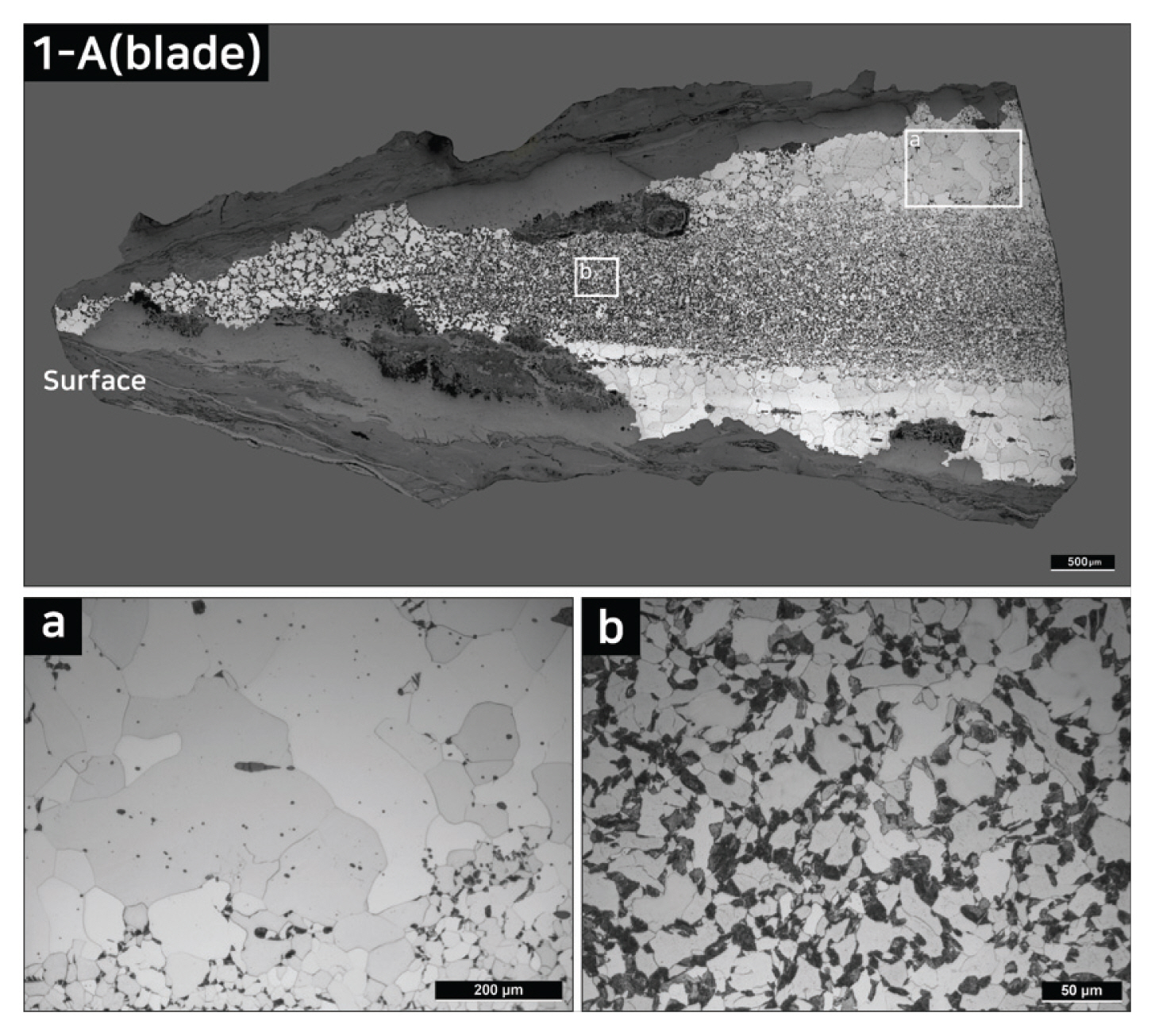

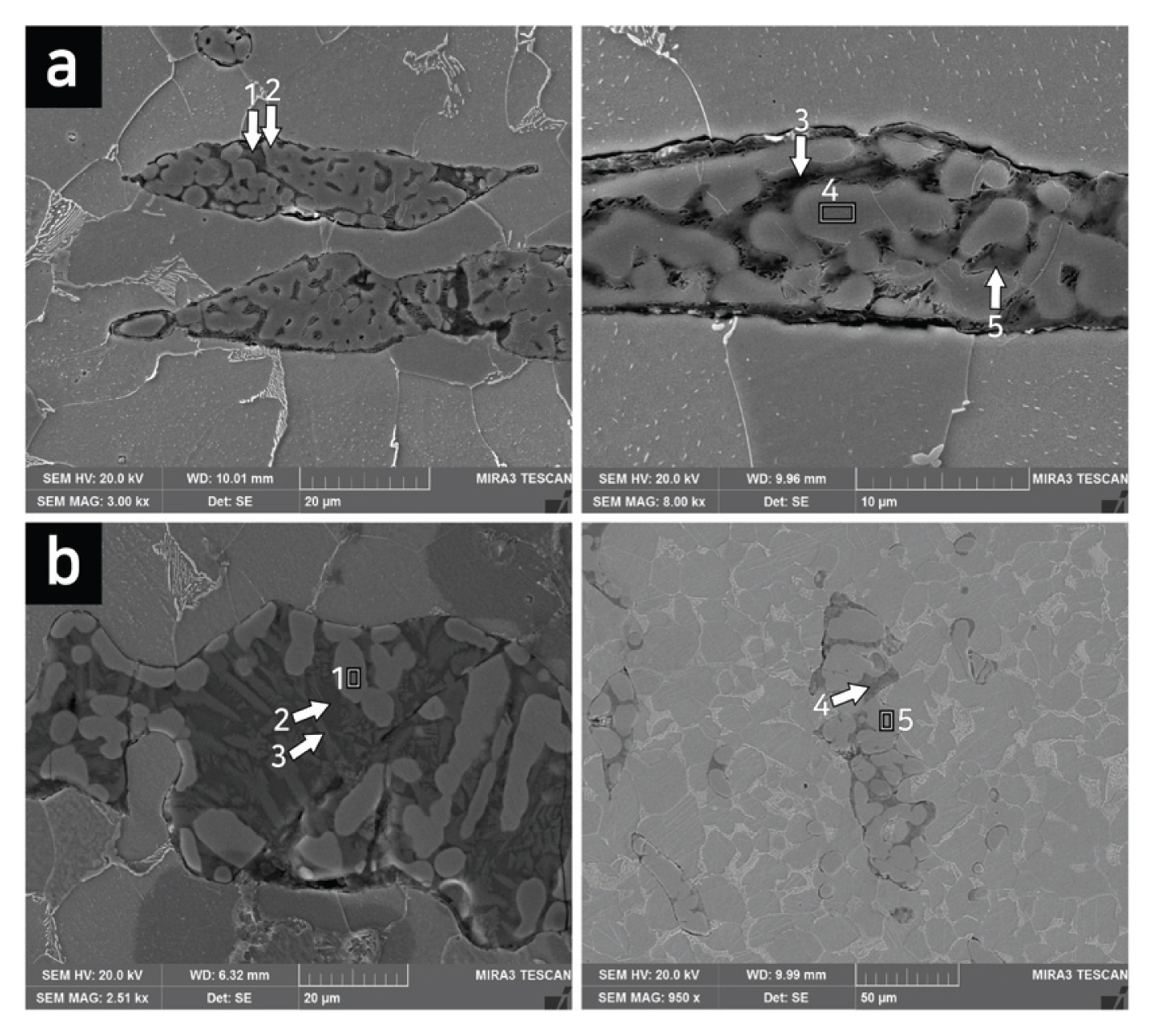

Figure 2 shows the microstructure of the blade side of the target sword with a ring pommel, where the top edge of its blade is displayed on the left side. This microstructure consists of three layers made of hypoeutectoid steel containing both ferrite and pearlite. Coarse ferrite is located at the upper and lower surfaces, while comparatively fine ferrite and pearlite are observed at the center. Figure 3 shows the microstructure of the back side of the sword with a ring pommel, where the upper part corresponds to the direction of the back surface. This microstructure contains both ferrite and pearlite, similar to the microstructure of the blade side. Coarse ferrite is observed at the internal part of the back side due to the large processing volume indicated based on different sizes of grains. The artifact was manufactured through repeated forging using hypoeutectoid steel with a high carbon content, leading to the existence of different grains sizes depending on forging degrees. The closer it is to the external part, the more ferrites closer to pure iron are observed. This phenomenon suggests decarburization due to shaping processes. Moreover, we conducted EDS analyses (Figure 4 and Table 2) and EDS mapping (Figure 5) of various types of nonmetallic inclusions. The analytic results verify the existence of wüstite and fayalite formed on glassy slag and a glassy matrix with a high Ca content.

Microstructure of Sample 1-A; (a) Rough ferrite at the top edge of the blade side (x200), (b) Fine ferrite and pearlite (x500).

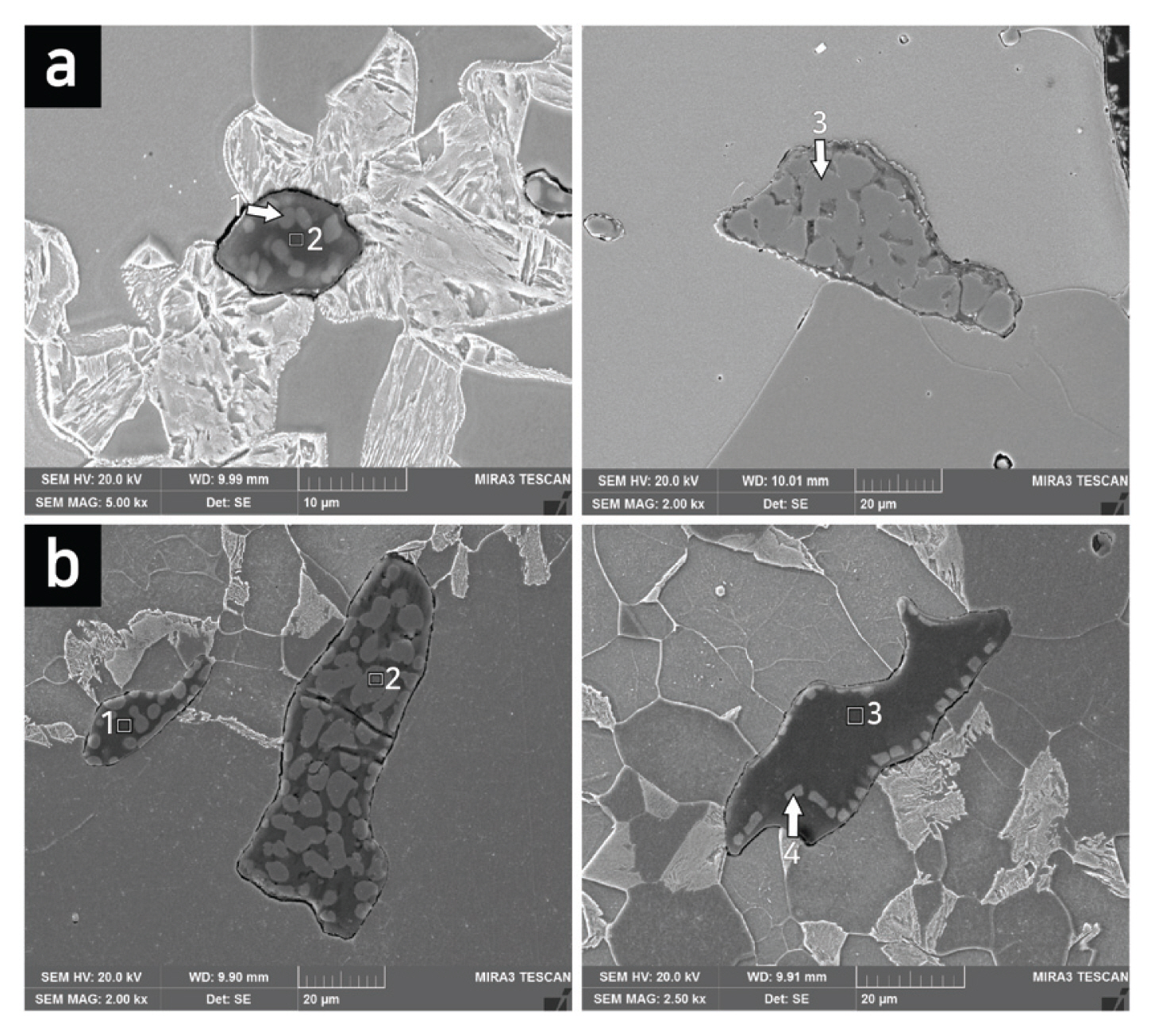

The SEM images and the location of an EDS analysis of No.1; (a) The blade side (1-A), (b) The back side (1-B).

3.1.2. A sword with a ring pommel excavated from a pit-tomb during the Proto–Three Kingdoms period (No. 2)

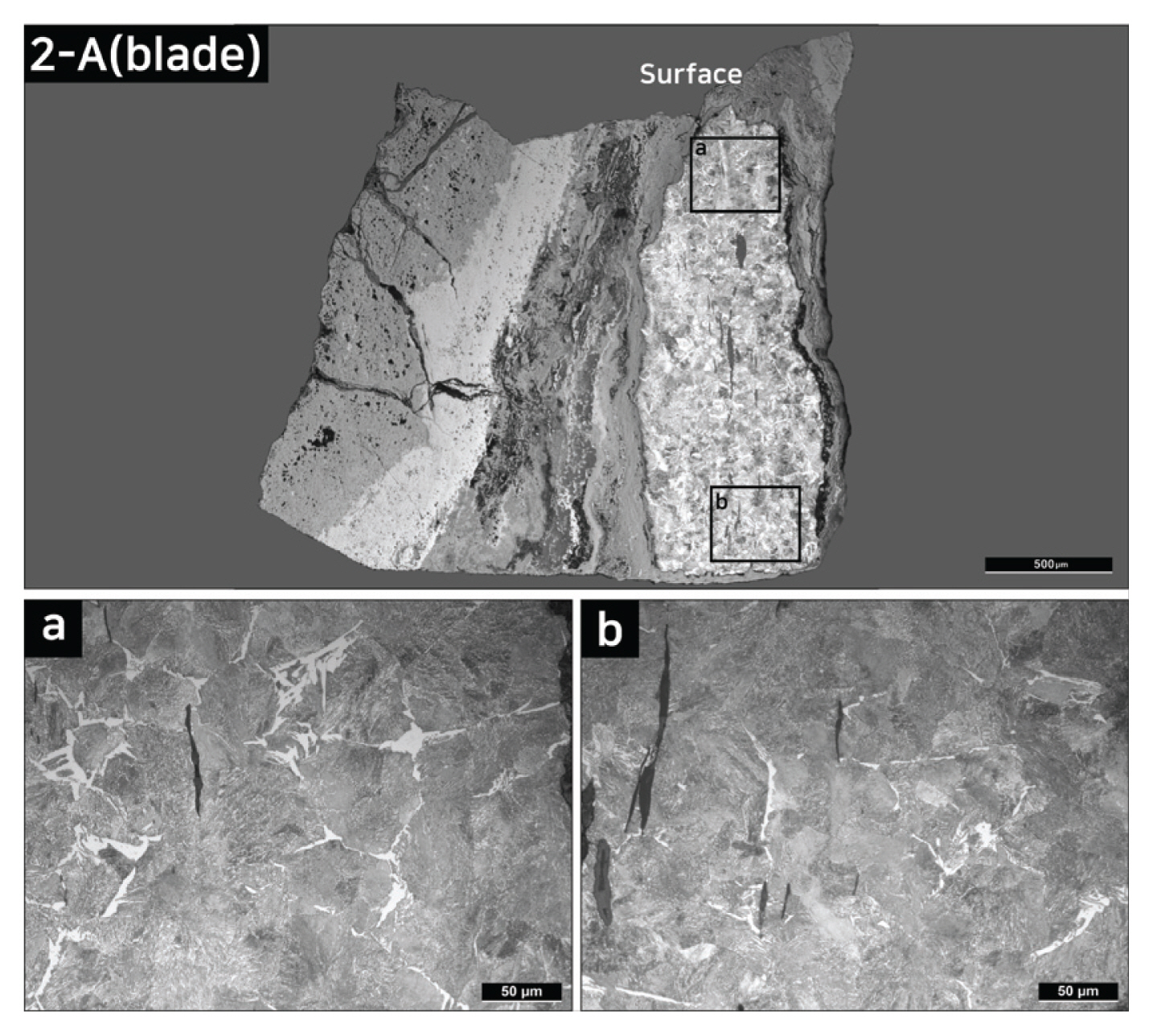

Figure 6 shows the microstructure of the blade side of a sword with a ring pommel excavated from a pit-tomb built during the Proto–Three Kingdoms period, where the top edge of the blade is displayed at the upper part. This microstructure generally includes large grains and pearlite contained high carbon content, suggesting that it was made of hypoeutectoid steel with a high carbon content.

Microcstucture of sample 2-A; (a) The structure of pearlite close to an eutectoid composition and partial widmanstätten ferrite (x500), (b) Pearlite and partial non-cubic ferrite formed on grain boundaries in the internal part (x500).

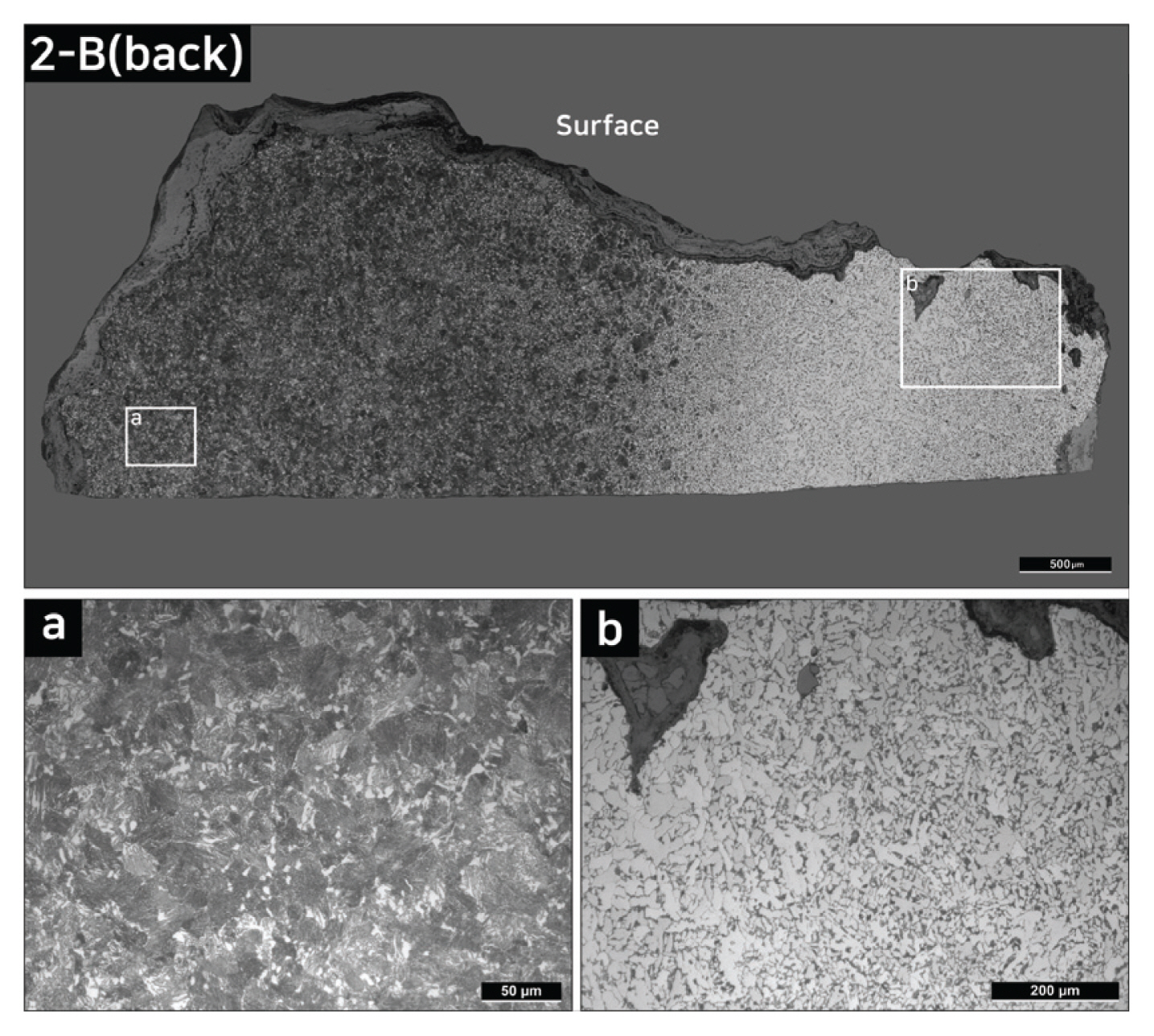

Figure 7 shows the microstructure of the back side of the sword with a ring pommel, where the upper part corresponds to the direction of the back surface. As the specimens with different left and right sides, pearlite and ferrite are generally mixed in a uniform size, but the left side is observed to be relatively dark compared to the right. On the right side, relatively coarse and non-cubic ferrite is observed.

Microcstucture of sample 2-B; (a) The structure of pearlite close to an eutectoid composition (x500), (b) The mixed structure of comparatively dense pearlite and ferrite (x200).

The artifact was manufactured through repeated forging using hypoeutectoid steel with a high carbon content, leading to the existence of elongated nonmetallic inclusions. Moreover, Ferrite due to decarburization was obserbed from back side (Figure 7) to the right. This decarbonization process would have been unintentionally conducted during the forging work.

The analytic results of nonmetallic inclusions (Table 3, Figures 8 and 9) indicate that these nonmetallic inclusions have the form of glassy slag and exhibit a high Al content. Polygonal particles that are comparatively brighter than other particles exhibit a high Ca content. Moreover, TiO2 of 1.07 wt% was detected from the glassy matrix. However, given that TiO2/SiO2 was 1% or less, TiO2 would have come from ores. (Kim, 2016)

The SEM images and the location of an EDS analysis of No.2; (a) The blade side (2-A), (b) The back side (2-B).

3.2. The archaeological site of Galsan-ri in Asan (N0.3)

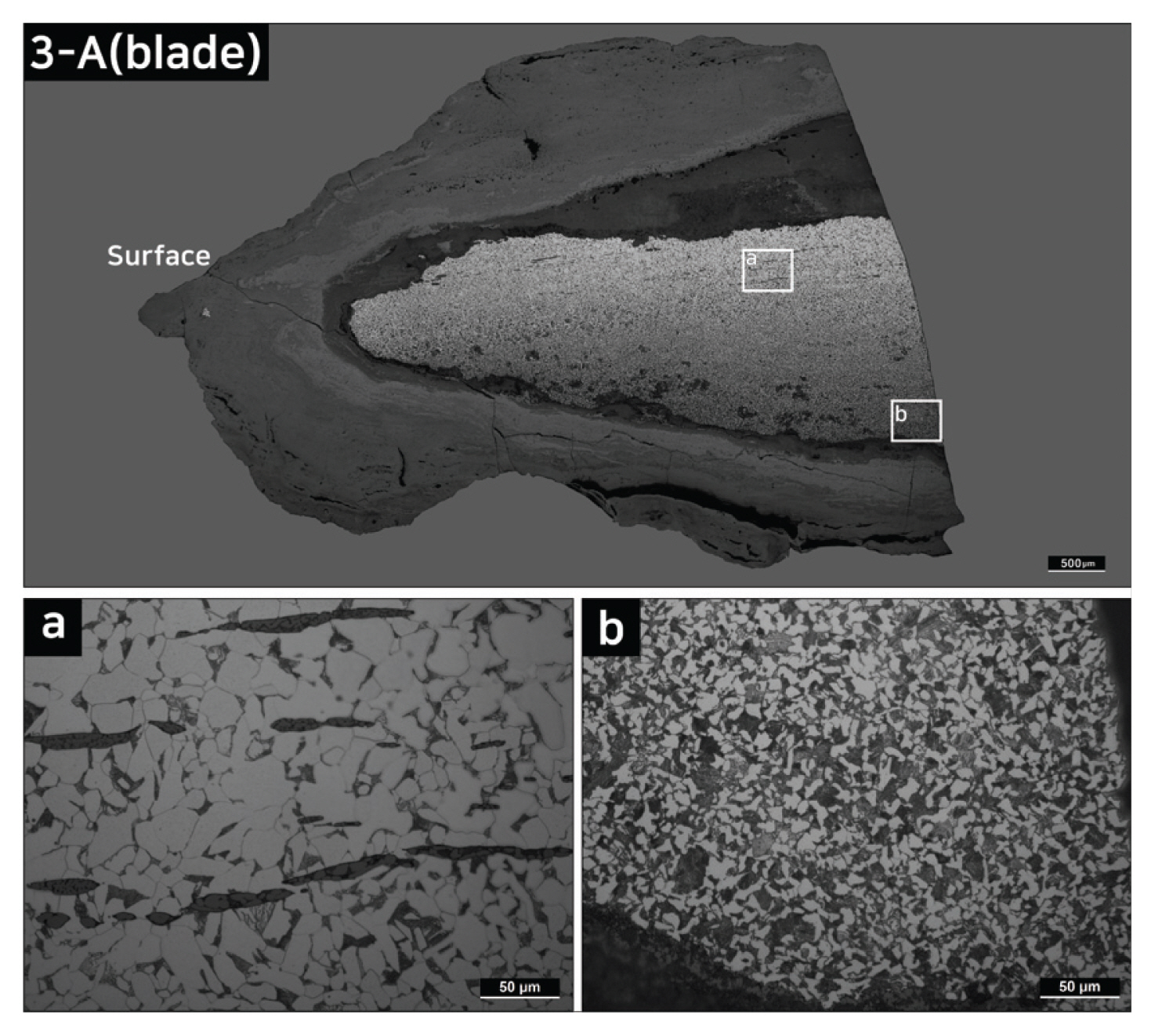

Figure 10 shows the microstructure of a sword with a ring pommel excavated from a pit-tomb built during the Baekje period, where the top edge of the blade is displayed on the left side. This microstructure generally exhibits a uniform mixture of ferrite and pearlite. Due to the forging process, more carbon is distributed at the bottom than at the top. In addition, nonmetallic inclusions, which became horizontally elongated due to repeated forging on the surface, are observed.

Microcstucture of sample 3-A; (a) Horizontally elongated nonmetallic inclusions (x500), (b) A structure containing a mixture of comparatively dense pearlite and ferrite (x500).

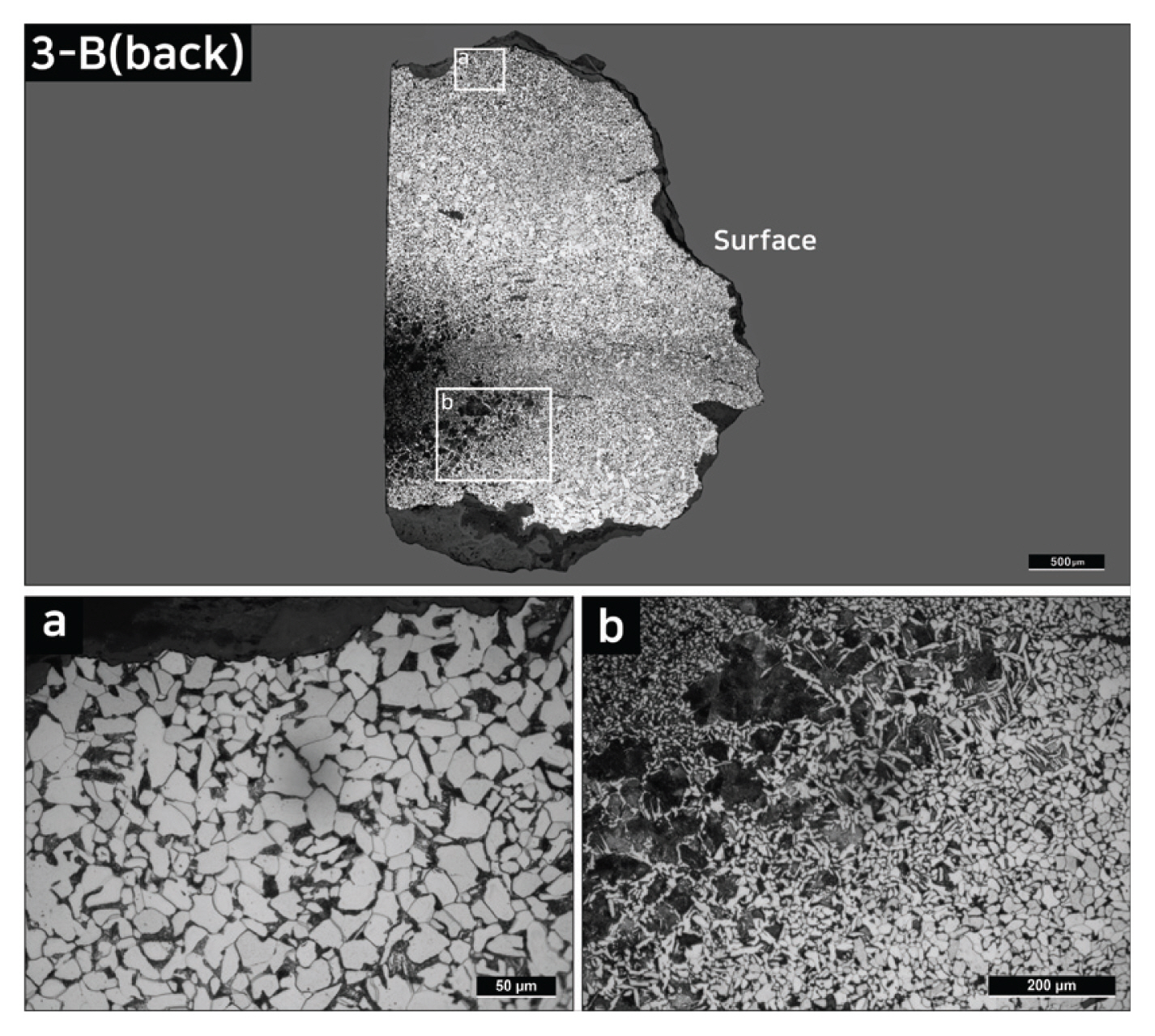

Figure 11 shows the microstructure of the back side, where the right part corresponds to the direction of the back surface. Carbon is concentrated in the base metal, and fine ferrite and pearlite are mixed.

Microcstucture of sample 3-B; (a) Ferrite structure (x500), (b) A rough pearlite structure, and a comparatively dense ferrite structure in the internal part (x200).

The artifact was manufactured through repeated forging using hypoeutectoid steel with a high carbon content. Due to the large amount of forging processing, a dense microstructure is observed and decarburization is confirmed.

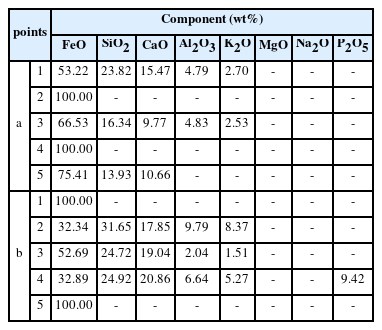

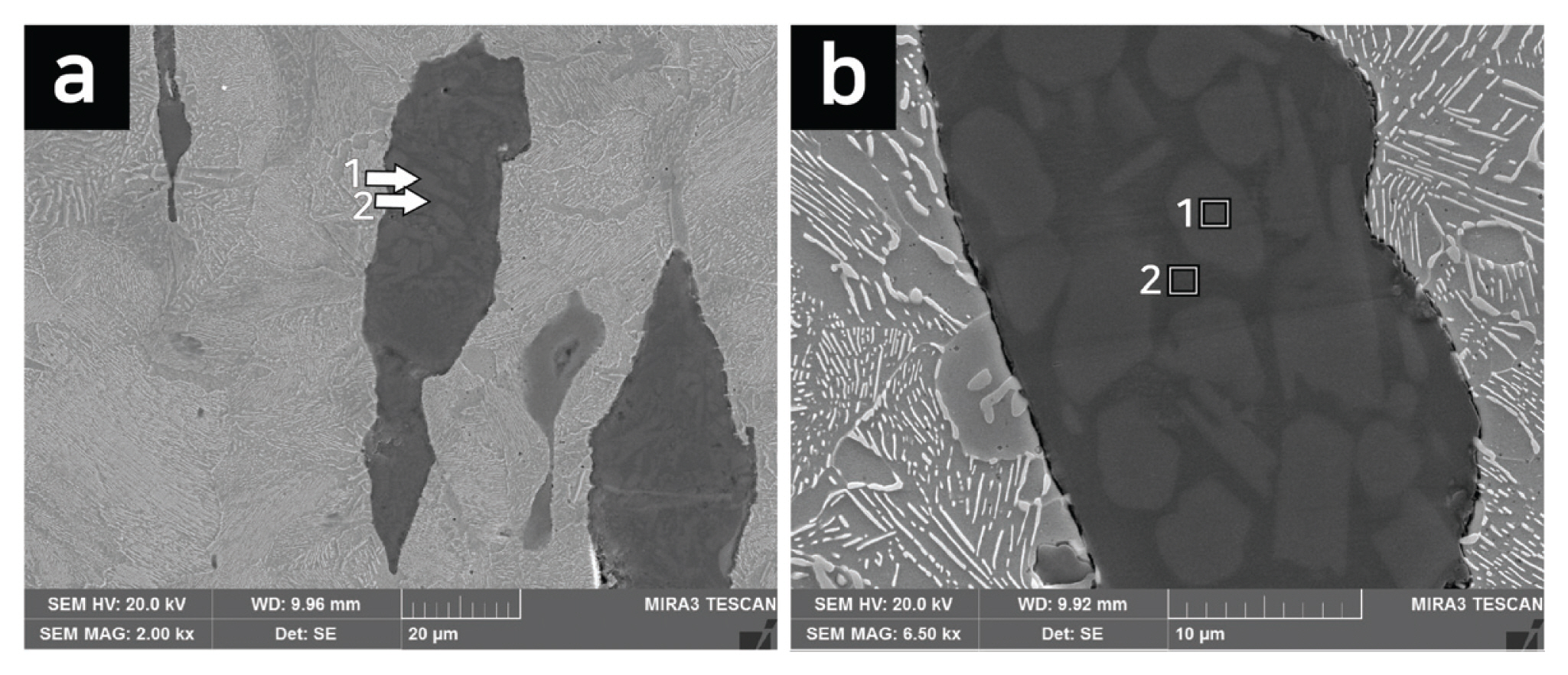

The analytic results of nonmetallic inclusions (Table 4, Figure 11) observed the formation of wüstite and fayalite on glassy matrix and a glassy slag, and the EDS mapping results (Figure 12) confirm the distribution of a high Ca content on the glassy matrix.

The SEM images and the location of an EDS analysis of No.3; (a) The blade side (3-A), (b) The back side (3-B).

4. DISCUSSION

4.1. Comparison of production techniques applied to iron swords excavated from the Asan and Cheonan

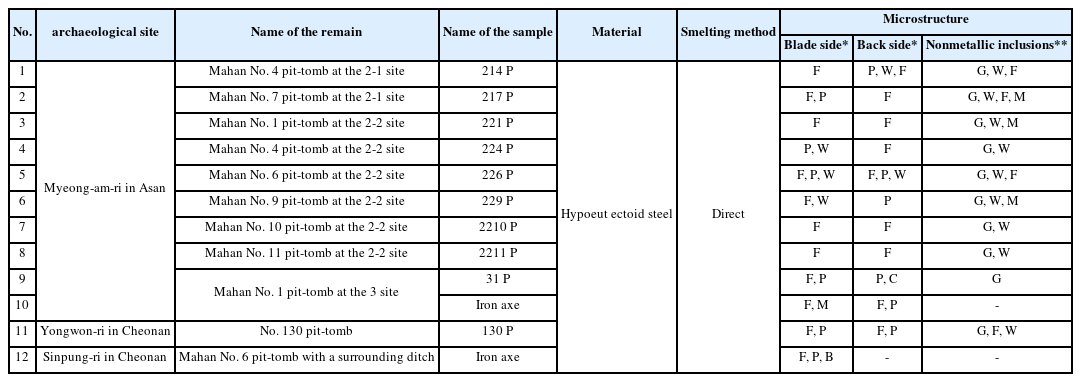

In this study, we examined the microstructures of three swords with ring pommels, which were manufactured during the Proto–Three Kingdoms period and the Baekje period and excavated from archaeological sites in Asan and Cheonan, and analyzed the components of their nonmetallic inclusions to identify techniques applied to produce these swords reflecting Mahan and Baekje styles. The target items were made of bloomery iron produced through direct smelting and formed by pounding hypoeutectoid steel. Accordingly, it is inferred that other heat treatment techniques, except shaping, were not applied (Figure 5).

The analytic results of swords with an undecorated ring pommels excavated from the Asan and Cheonan regions

Moreover, we reviewed existing studies on swords with ring pommels excavated from other archaeological sites in Asan and Cheonan to compare them with our research targets (Cho, 2015)(Table 6). The entire swords with an undecorated ring pommels excavated from the archaeological site of Bakjimeure, Myeong-am-ri in Asan, which was established from the late second century to the late third century, were made of hypoeutectoid steel. Additionally, no traces of intentional hardening treatments, such as carburization and quenching, were found. A sword with an undecorated ring pommel excavated from the archaeological site of Yongwon-ri in Cheonan, which was established during the late fourth century, was also made of hypoeutectoid steel and contained only a welded microstructure.

However, existing studies (Park et al., 2000; Cho, 2015)(Table 6) on iron axes and iron spears excavated from the same archaeological site revealed the existence of martensite, a heat-treated structure resulting from quenching, in these remains. A steel structure with a high carbon was observed in the blade region of iron spears, and traces of carburization, conducted to control carbon content, were identified in various parts of these spears.

Iron remains excavated from the archaeological site of Sinpung-ri in Cheonan, which was established in a period from the late third century to the early fourth century, were made of hypoeutectoid steel or eutectoid steel. Accordingly, it is presumed that these items were produced by forging bloomery iron. Particularly, iron sickles excavated from a pit-tomb with a surrounding ditch built during the Proto–Three Kingdoms period included bainite structures resulting from quenching and rapid cooling (Sung et al., 2014)(Table 6).

The analytic results indicate that heat treatment techniques for hardening specific parts were applied to several iron remains from nearby regions and similar periods but not to the target swords with ring pommels. Thus, we analyze that the target swords were produced as ceremonial items rather than weapons.

4.2. Comparison of CaO ratios

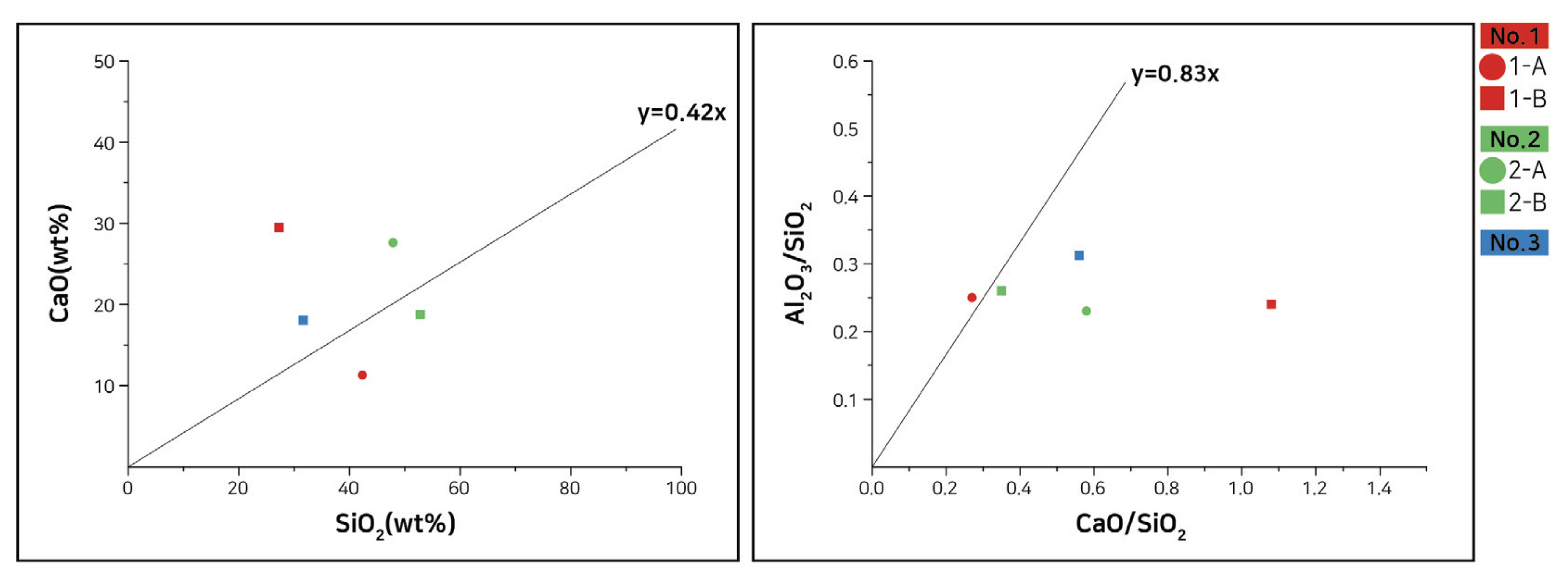

CaO is influenced by not only raw materials but also furnace walls and fuel components (Lee et al., 2017). In terms of nonmetallic inclusions, if the CaO to SiO2 ratio based on a glassy matrix, which is affected the most significantly by a Ca content, is generally 0.42 or higher, it is considered that calcareous substances were intentionally input as slag generation agents in a furnace (Kim, 2014; Lee et al., 2017). In the iron manufacturing process, CaO serves as a slag generation agent that facilitates smooth separation between slag and metal iron by reducing the viscosity of SiO2 and Al2O3 and enhancing their fluidity (Kim, 2012). Furthermore, Cho (2015) and Lee et al. (2017) reported that the Al2O3 to SiO2 ratio can be used as an index for distinguishing similar smelting processing systems (e.g., ores, furnace walls, and fuel).

We applied these analytic results to our research targets and calculated the required ratios. As shown in Figure 14, calculation results verified that slag generation agents were added to produce the entire target items. However, the values of ratios differed on the blade side (A) and the back side (B) despite the use of the sample extracted from the same remains. Particularly, as for the ratios of CaO/SiO2 and (Al2O3/SiO2)/(CaO/SiO2), the ratio values of samples of the target No. 1 sword were marked at different locations on A and B.

On the graph of (Al2O3/SiO2)/(CaO/SiO2), the ratio values of 1-A and 2-B are located to be closer to y = 0.83 x than the other samples. This linear function (y = 0.83 x) was derived from an existing experimental study on reproducing ancient iron smelting techniques. For this reason, different values may be obtained when this function is applied to practical iron remains. To overcome challenges, further extensive research on the ratios of CaO-SiO2-Al2O3 will be required.

Additionally, the calculation results show the distribution of the ratio of l2O3 to SiO2 in a certain range despite a difference in CaO content, thereby suggesting that the target items were produced based on a similar smelting processing system.

5. CONCLUSIONS

In this study, we examined the microstructures of two swords with an undecorated ring pommels excavated from the archaeological sites of Cheongdang-dong and Guryong-dong in Cheonan and a sword with an undecorated ring pommel excavated from the archaeological site of Galsan-ri in Asan and analyzed the components of their nonmetallic inclusions. Moreover, we compared the target swords with remains excavated from other nearby archaeological sites to identify distinct periodic and regional characteristics of the target swords. Based on the analytic results, we derived the following conclusions.

The results of examining microstructures indicate that the target swords were formed by using hypoeutectoid steel with a high carbon content through repeated forging. Horizontally elongated nonmetallic inclusions caused by these processes were observed, whereas traces of specific heat treatment were not. Furthermore, it is analyzed that decarburization unintentionally occurred during the production processes.

The results of analyzing the components of nonmetallic inclusions indicate that most nonmetallic inclusions have the form of glassy slag. In some cases, wüstite or fayalite was observed. The existence of wüstite suggests that iron ores were smelted through a direct smelting technique.

The results of conducting the EDS analysis and EDS mapping based on the glassy matrices of nonmetallic inclusions exhibited a comparatively high Ca content, with exceptions in some cases. Based on these results, it is inferred that slag generation or fusing agents were intentionally added. There is also a possibility of the inclusion of fuel ashes or smelting using iron ores with a high Ca content.

The comparison results indicate that heat treatment techniques were not applied to base swords with ring pommels produced during the Mahan and Baekje periods despite the existence of such techniques. Thus, we analyze that the target swords were produced as ceremonial items rather than weapons.

This study has a limitation in that it cannot identify distinct production techniques depending on regions and periods applied to swords with an undecorated ring pommels manufactured during the Mahan and Baekje periods and excavated from the Asan and Cheonan regions. In this regard, follow-up research will be required to analyze the characteristics of ironware production techniques used during the Mahan and Baekje periods by comparing iron remains excavated from the target regions with those from other archaeological sites.

ACKNOWLEDGEMENT

The research conducted for this paper was funded by the Government (Ministry of Education) in 2022, and supported by the Conservation Research Support Project of the Science & Engineering Basic Research Project hosted by the National Research Foundation of Korea (NRF-2020R1I1A2072253).