A Characteristic Analysis of Glass Beads Excavated from the Naedeok-ri Site in Gimhae

Article information

Abstract

This study conducted a cross-sectional analysis of 10 beads and a surface analysis of 38 beads among 48 glass beads excavated from the Naedeok-ri site in the Gimhae region, Korea. According to the cross-sectional analysis results, all glass beads were cobalt blue, and depending on the period, the bead colors from wooden coffin tomb No. 19 from the Proto-Three Kingdoms period and wooden coffin tomb No. 92 from the Three Kingdoms period were determined to be ultramarine and Wedgewood blue. According to the surface analysis results, the colors of the beads were divided into blue from the Proto-Three Kingdoms and Three Kingdoms eras, and brown from the Joseon Dynasty. Furthermore, the size of the beads was estimated to be Gimhae “small-sized”. These small beads were popular until the late Gaya period. As a result of analyzing the composition of the glass, only potash 1 type was confirmed in the cross section, but lead, potash, and soda glass were confirmed in the surface analysis. This is because glass from the Proto-Three Kingdoms period was easily broken, and glass from the Three Kingdoms period was excavated relatively complete. Through this study, Gimhae Naedeok-ri is confirmed to be a group that uses glass with various ingredients. These results reveal a trend moving in the following order: lead-barium II → potash I·II → soda alumina → potash III·lead glass.

1. INTRODUCTION

Gimhae is a city between Busan and Changwon in South Gyeongsang Province and lies along the coast near the Nakdong River. This region has had a higher frequency of excavations of ancient glass compared with other Gyeongsang culture regions. Gimhae was the capital of Geumgwan Gaya, the central state of the Early Gaya Federation, and at the time, it obtained glass beads through various maritime exchanges. As traces, glass beads have been identified at 15 archeological sites in the Gimhae region, including the Hoehyeon-ri shell midden, Chilsan-dong, Mangdeok-ri, Bonsan-ri, Yeorae-ri, Upper Deokjeong, Jukgok-ri, Bukbu-dong, Deoksan-ri, Songhyeon-ri, Samgye-dong, Anyang-ri, and Yuha-ri, in addition to the major sites, the Yangdong-ri and Daeseong-dong tombs. (Gimhae National Museum, 2019)

The scientific analysis of glass beads from Geumgwan Gaya initially began at the Yangdong-ri remains in Gimhae, where a total of 62 pieces of glass beads were analyzed and the characteristics of their chemical compositions were sorted by period. (Kim et al., 1998; Kim, 2002). Later, non-destructive analysis was applied to the round glass beads excavated from the Yangdong-ri site to classify the glass bead shapes and determine their chemical compositions. (Gimhae National Museum, 2012). In recent years, scientific analyses have been conducted to investigate glass beads from Geumgwan Gaya and to develop a comprehensive interpretation of the shapes, colors, production techniques, and chemical compositions of these beads. Based on these data, the chemical compositions of glass beads from Geumgwan Gaya can be classified according to their external characteristics. (Kim et al., 2021; Kim, 2023). Unlike other Gaya cultural spheres, the glass beads from Geumgwan Gaya have been characterized mainly as potash glass beads, in addition to being cobalt blue and copper blue beads. (Kim et al., 2021; Kim, 2023). However, the published analysis results on the glass beads from Gimhae have mainly addressed the Yangdong-ri and Daeseong-dong tombs, major ruins in this region, while there has been a general lack of analytical results related to the nearby remains. Thus, this study aims to explore the cultural aspects of ancient Gaya glass and the glass culture of the Gimhae region after the Gaya period. Therefore, it examines the external characteristics, such as shape, color, and production technique, of glass beads excavated from the Naedeok-ri site in Jangyu-myeon, which was investigated in 1996. Moreover, chemical composition analysis is conducted utilizing energy-dispersive X-ray fluorescence spectroscope (ED-XRF), a non-destructive analysis technique, and scanning electron microscopy with energy dispersive spectroscope (SEM-EDS), another sample analysis technique.

2. SCOPE OF RESEARCH

2.1. Introduction to site

The Naedeok-ri site in Gimhae contains remains in the Jangyu area from the late Geumgwan Gaya period. The architectural style of this ancient tomb is estimated to date from the mid-5th century to the early 6th century. This period corresponds to the period when Geumgwan Gaya began to decline after the historical event of Goguryeo’s expedition in 400 CE. Nevertheless, the architectural style may be related to the phenomenon followed by the dissolution of the social structure in the early period of Geumgwan Gaya when this style was displayed in the Daeseong-dong and Yangdong-ri tombs when it reached its peak. The wooden coffin tomb No. 19, which may date back to the Proto-Three Kingdoms period, at the Naedeok-ri site in Gimhae was identified as a chieftain-level tomb, similar to the Daeseong-dong and Yangdong-ri tombs. Bronze mirrors and swords were excavated from it, along with glass necklaces. In the case of buried glass products, 87 pieces of glass beads were found in the wooden coffin tomb No. 19, and a small number of glass pieces were excavated from tombs formed during the Three Kingdoms period after the 4th century. Later, typical brown beads began to appear during the Joseon Dynasty. Thus, the Naedeok-ri site in Gimhae consists of a tomb that shows the style of the late Geumgwan Gaya period. Additionally, it may further describe the process of the decline of Geumgwan Gaya during its early period, as well as the period of the arrival of Silla troops. Through a scientific analysis of glass beads, this study intends to determine the temporal precedence of these events based on these remains.

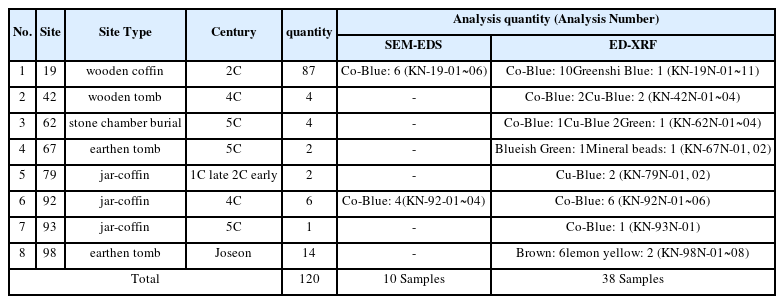

2.2. Analysis Samples

The remains subjected to analysis consist of two pieces from the Proto-Three Kingdoms, five pieces from the Three Kingdoms period, and one piece from the Joseon Dynasty. In the case of the Proto-Three Kingdoms and the Three Kingdoms period samples, the creation of the remains may date back to between the 2nd and 5th centuries. The colors of these beads are mainly blue, including cobalt blue and copper blue. In the case of the Joseon Dynasty, the bead colors are identified as brown and light yellow (buff). Forty-eight beads were subjected to analysis, consisting of 10 beads for SEM-EDS analysis and 38 beads for ED-XRF analysis (Table 1).

3. METHOD

3.1. Cross-Section Analysis

Cross-sectional samples of the glass beads are prepared for analysis of the beads’ microstructures and internal compositions. These selected samples are fabricated to obtain samples most suitable for the selected analysis methods using the pretreatment process described as follows.

A cross-sectional sample is prepared with epoxy resin, and then ground and polished with sandpapers (Nos. 400, 600, 800, 1200, 2400, and 4000) and diamond abrasives (6, and 1 μm) to flatten the cross-section subject for analysis. Subsequently, to prevent contamination of the sample cross-section, the sample is cleaned three times for 5 minutes at each polishing stage using an ultrasonic cleaner.

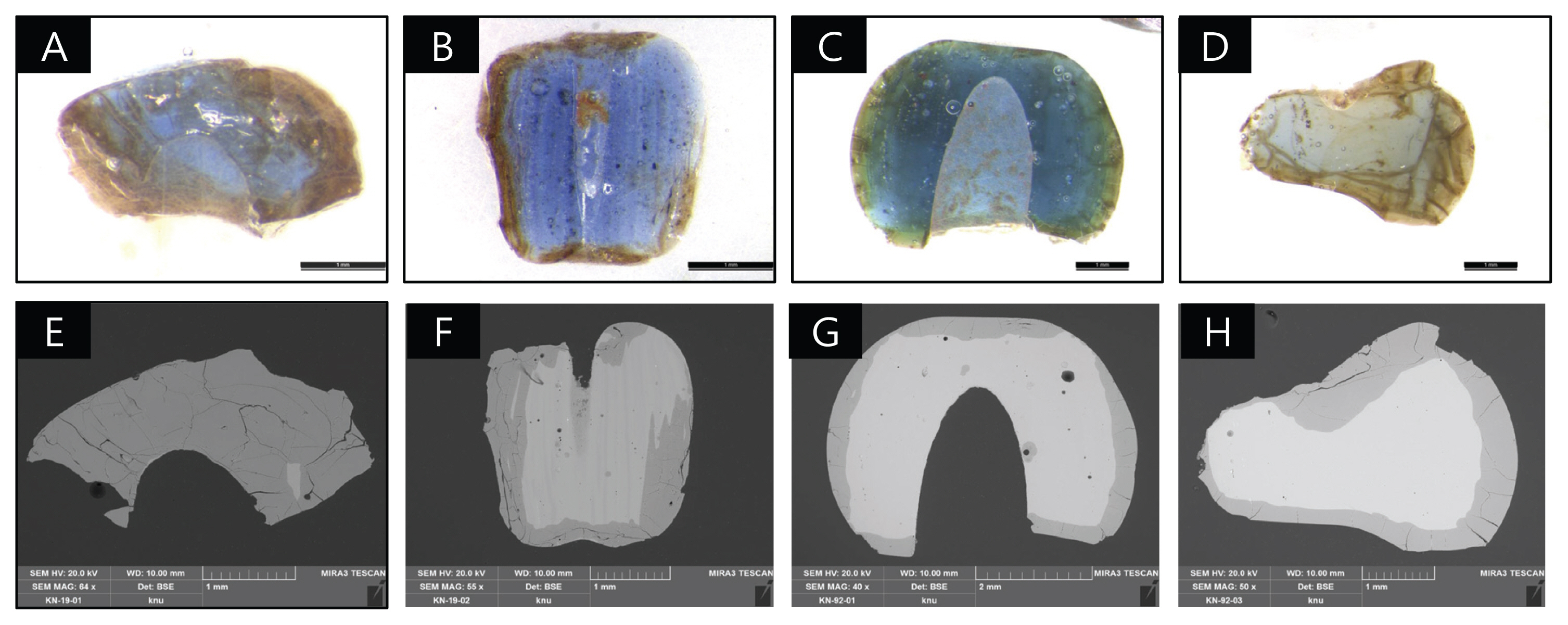

3.1.1. Cross-Section Characteristics

The microstructures of the cross-sections of the bead pieces are examined using an optical microscope (Leica MZ75, DEU), and include characteristics such as color, weathering state, and weathering rate. Then, defect structures, such as bubbles, cracks, impurities, and the weathered layer are observed on the same cross-section utilizing a scanning electron microscope (SEM, Tescan MIRA3-LMH, CZE).

3.1.2. Cross-Section Composition

The cross-section compositions are measured using an energy dispersive X-ray spectroscope (EDS, Bruker X-flash4010, DEU) attached to the SEM with a voltage of 20kV and a measurement time of 120 seconds.

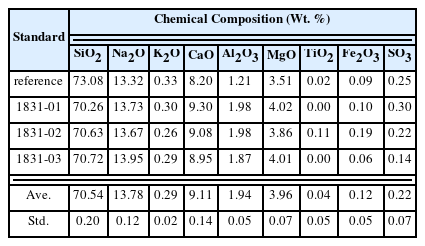

The accuracy and reproducibility of the composition of the cross-section of the glass beads are confirmed by comparing the measurement results of the standard sample (SRM 1831) three times under the same measurement conditions (Table 2).

3.2. Non-Destructive Analysis

Because ancient glass beads are small artifacts, it is difficult to identify their visible characteristics through typical naked-eye observation. This study intends to determine the characteristics observed on the surfaces of round glass beads using a microscope and an EDS spectrometer.

3.2.1. Surface Characteristics

The external characteristics of glass beads are determined in terms of color, size, shape, and production technique. The color of the glass beads is determined using the Munsell Bead Color Book (Pantone, USA). Color notation followed the standards suggested by previous research (Kim, 2002; Kim, 2013). The size of the glass beads is measured using an image processing program (PicMan, Wafer Masters, Inc., USA). The measurement method involved using the scale bar of an optical microscope as a reference and measuring the inner diameter, outer diameter, and length (Kim, 2019; Kim et al., 2021; Kim, 2023). The shape and production technique of the glass beads are observed using a portable optical microscope. The front and sides of the beads were photographed, and a white balance was applied based on a color chart (Gray 20%) to maintain the same environmental conditions. The shape and production technique of the glass beads are observed using an optical microscope. The front and sides of the beads were photographed, and an additional photograph was obtained in which both the front and sides of the beads were visible after tilting them to identify their shapes.

3.2.2. Surface Composition

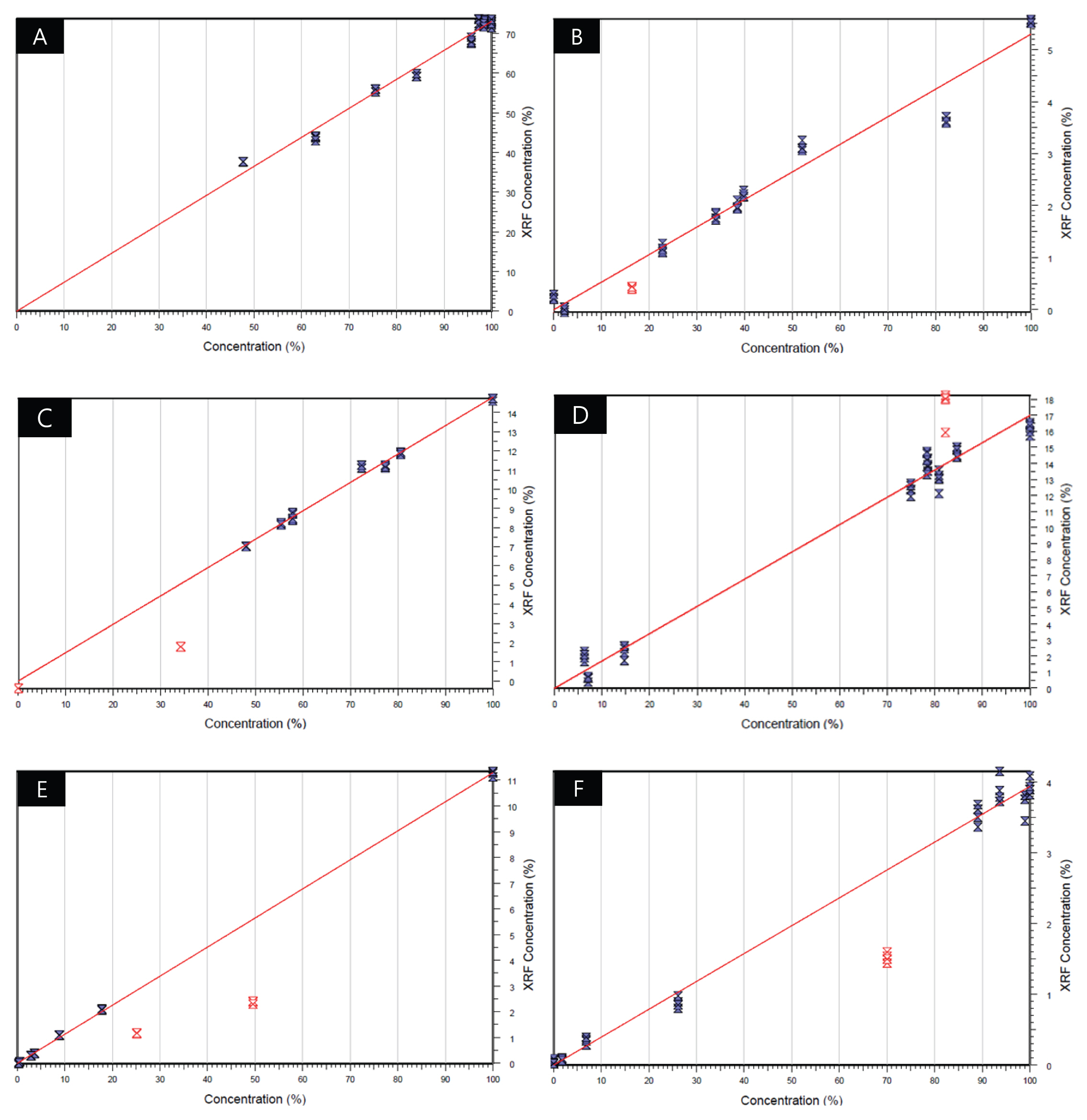

HH-XRF spectrometry is applied to determine the surface composition of the round glass beads. HH-XRF is a widely used analysis technique in cultural property analysis because it can provide information on surface composition without damaging the artifact. However, to overcome its limitations in accurately analyzing the composition of glass beads due to surface weathering, a calibration curve was prepared utilizing glass standard references (SRM 610, 612, 620, 621, 1831; Corning B, C, D). The data excluded from the calibration curve are marked in red in Figure 1. A Hand Held X-ray Fluorescence (HH-XRF) Spectrometer (Bruker 5G, DEU) is employed to determine the surface composition due to its advantages of portability and detection performance under atmospheric conditions for light elements such as Na, Mg, Al, Si, S, P, and Cl, which are principal components of glass. The measurements were obtained for 60 seconds using Glass Major conditions by applying a calibration curve prepared in a measurement environment with a 3 mm collimator, vacuum environment (Table 3).

A calibration curve for principal components based on glass standard reference: (A) Si, (B) Al, (C) Ca, (D) Na, (E) K, (F) Mg.

4. RESULTS AND DISCUSSIONS

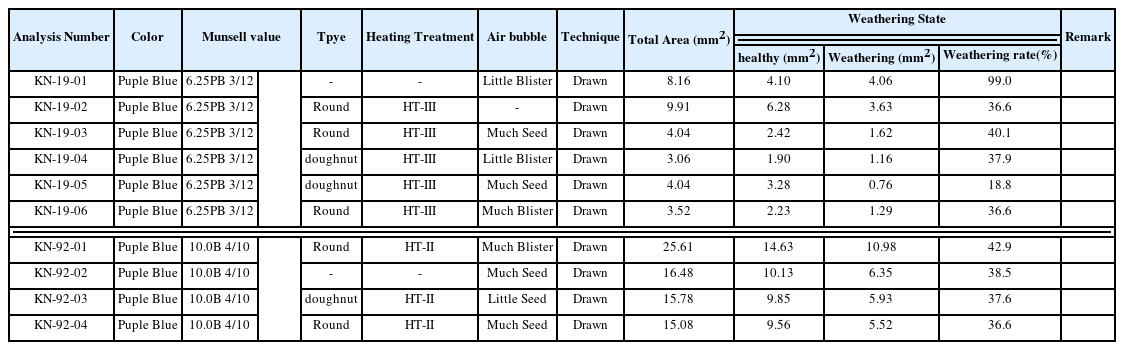

4.1. Cross-Section Characteristics

The observed cross-sectional characteristics of 10 glass beads from Naedeok-ri, Gimhae, are summarized as follows (Table 4). All these glass beads are cobalt blue. Wooden coffin tomb No. 19, from the Proto-Three Kingdoms period, and wooden coffin tomb No. 92, from the Three Kingdoms period, are matched with ultramarine and Wedgewood blue using the Munsell Color System. The same results are identified as cobalt blue, as in Yangdong-ri and Daeseong-dong in Gimhae (Kim, 2023). The production technique is determined through bubble arrangement to be a drawn technique, and severe weathering was identified on the outer surface of the beads based on the measurement of the weathering rate.

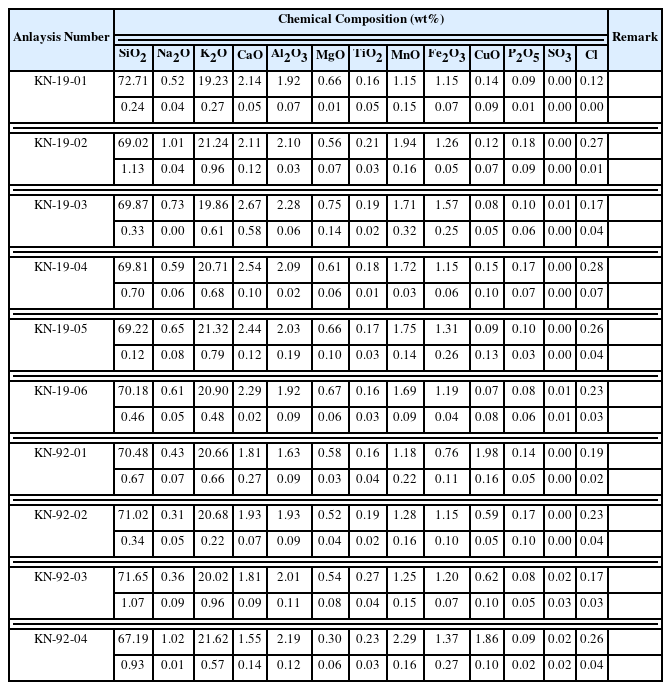

4.2. Cross-Section Composition

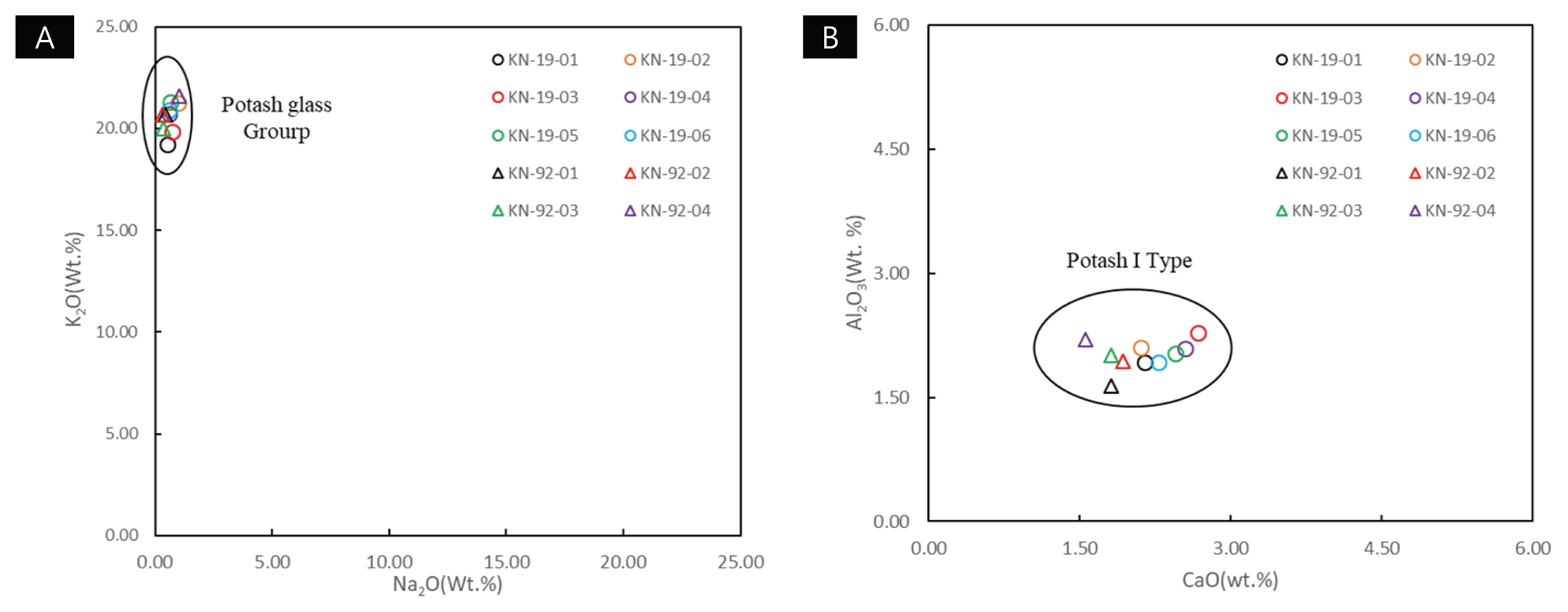

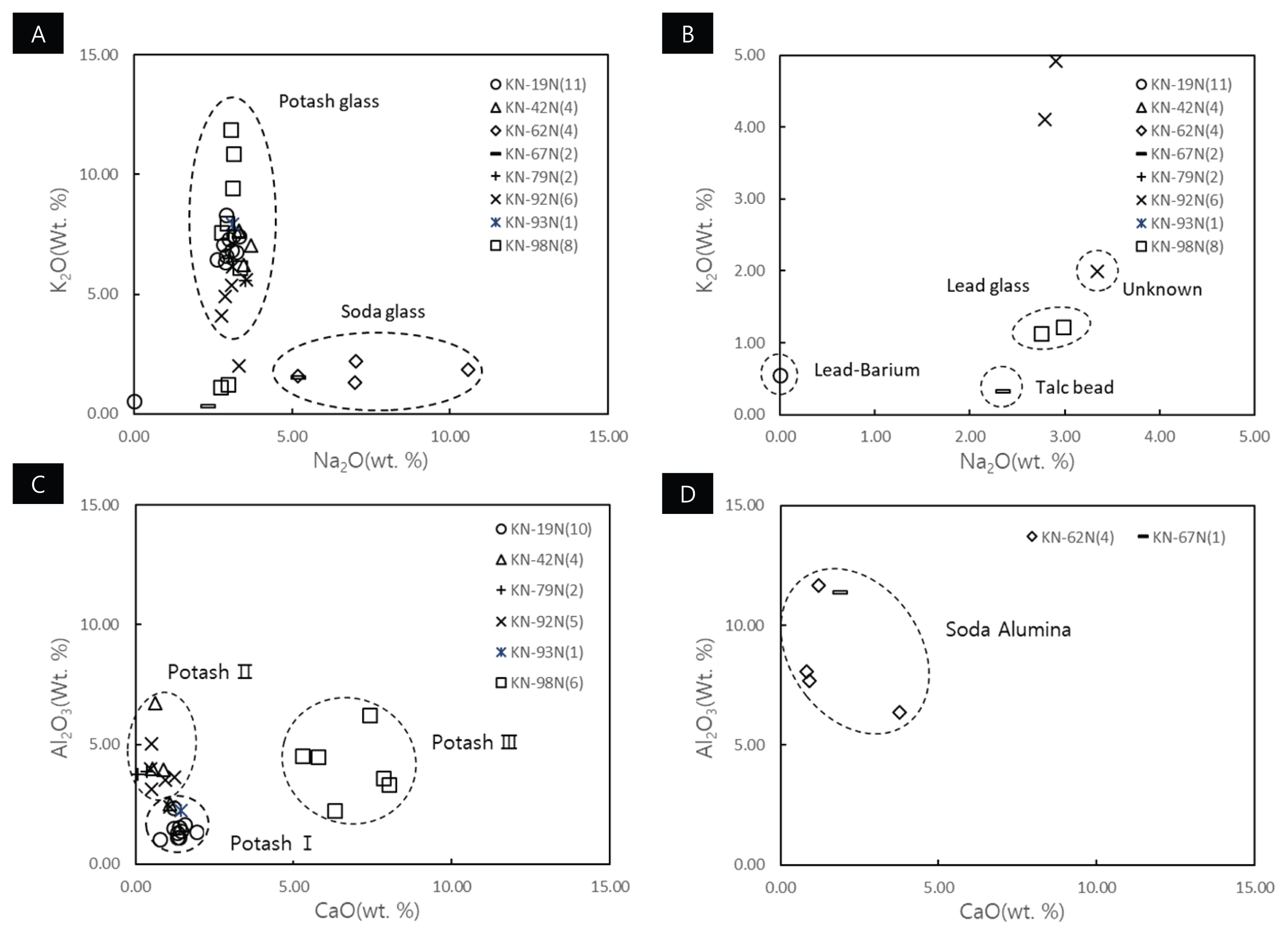

To determine the cross-sectional composition of 10 glass beads from Naedeok-ri, Gimhae, the microstructure variables (color, weathering state, and weathering rate) are measured three times and summarized with averages and standard deviations. The results are diagrammed according to the flux and stabilizer components to evaluate the composition characteristics of the glass beads (Table 5, Figure 3). The flux characteristics of the glass beads from the Naedeok-ri site, Gimhae are represented by the potash glass groups, including soda (Na2O) of 0.31–1.02% and potash (K2O) of 19.23–21.62%. The stabilizer characteristics correspond to potash type I in that both lime (CaO) and alumina (Al2O3) are less than 3%. The colorant is identified as cobalt (Co) based on a high composition of manganese oxide (MnO) and iron oxide (Fe2O3). Cobalt has a high color development power, enough to produce blue in small amounts of less than 0.1%. Because it is contained in trace amounts in ancient glass, it is not detected during EDS analysis. Since cobalt is produced together with manganese when extracted from a mine, cobalt can be inferred based on the manganese content (Kyriaki P et al., 2011).

Classification results of the chemical composition of glass beads from the Naedeok-ri site, Gimhae. (a) fluxes, (b) stabilizers.

All ten glass beads from the Naedeok-ri site correspond to potash type I. Considering the analysis results of glass beads excavated from the Yangdong-ri and Daeseong-dong tombs in Gimhae, despite the influx of low-soda alumina in the early 3rd century, potash type I glass beads had been in continuous use throughout the entire Geumgwan Gaya period. Because these results are obtained from broken beads, the possibility exists that other materials may have been introduced into the glass. Therefore, this study proceeded to compare the results of the surface composition analysis by increasing the number of analysis samples, mainly of the round beads (Figure 4).

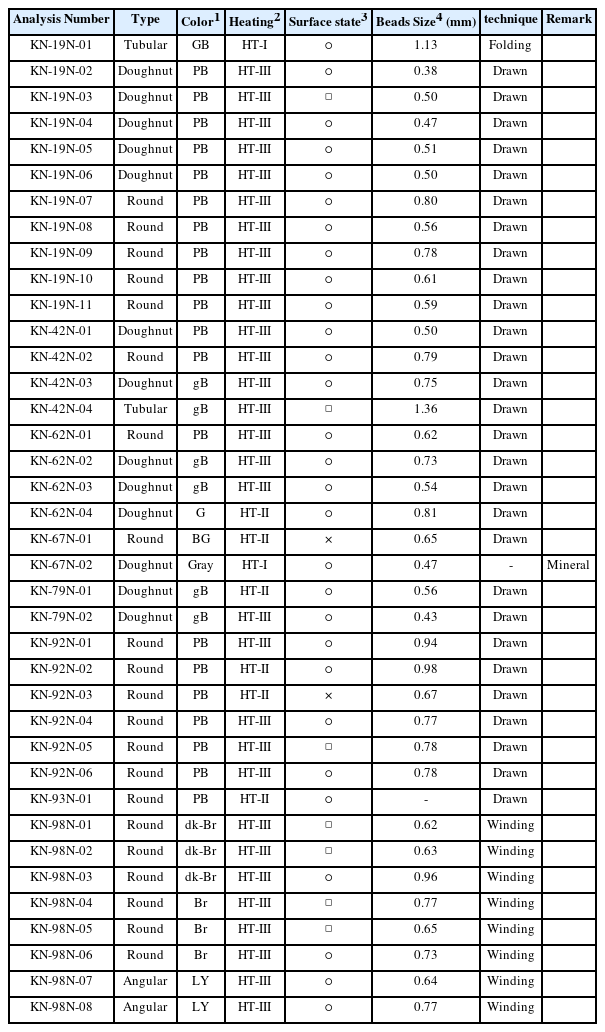

4.3. Surface Characteristics

The surface characteristics of 38 round glass beads excavated from Naedeok-ri, Gimhae, are investigated, and shape, color, heat treatment, surface conditions, size, and production technique data are summarized as follows (Table 6).

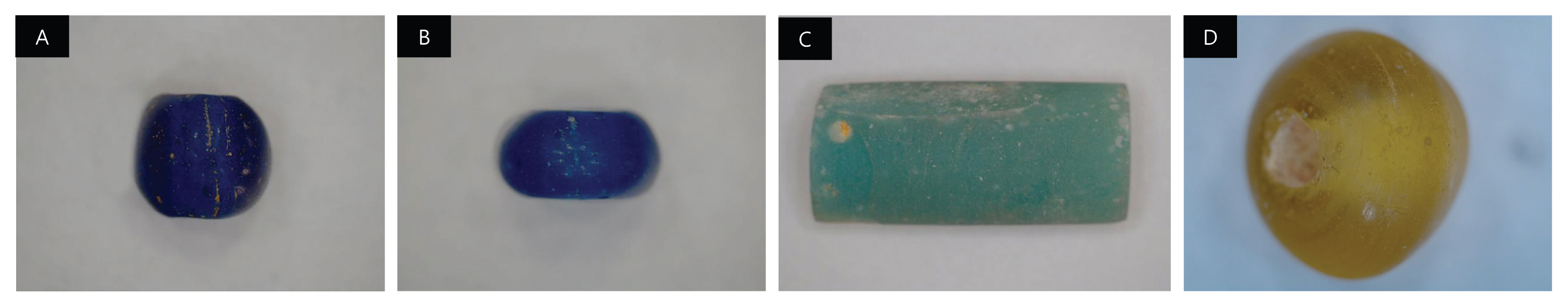

The shape of the beads is classified based on the outer diameter of the bead divided by its length. There are 20 round shapes, 13 donut shapes, 2 tubular shapes, and 2 square shapes (Figure 5).

Shapes of glass beads at Naedeok-ri site, Gimhae. (A) Round bead, (B) Donut bead, (C) Tubular bead, (D) Square bead.

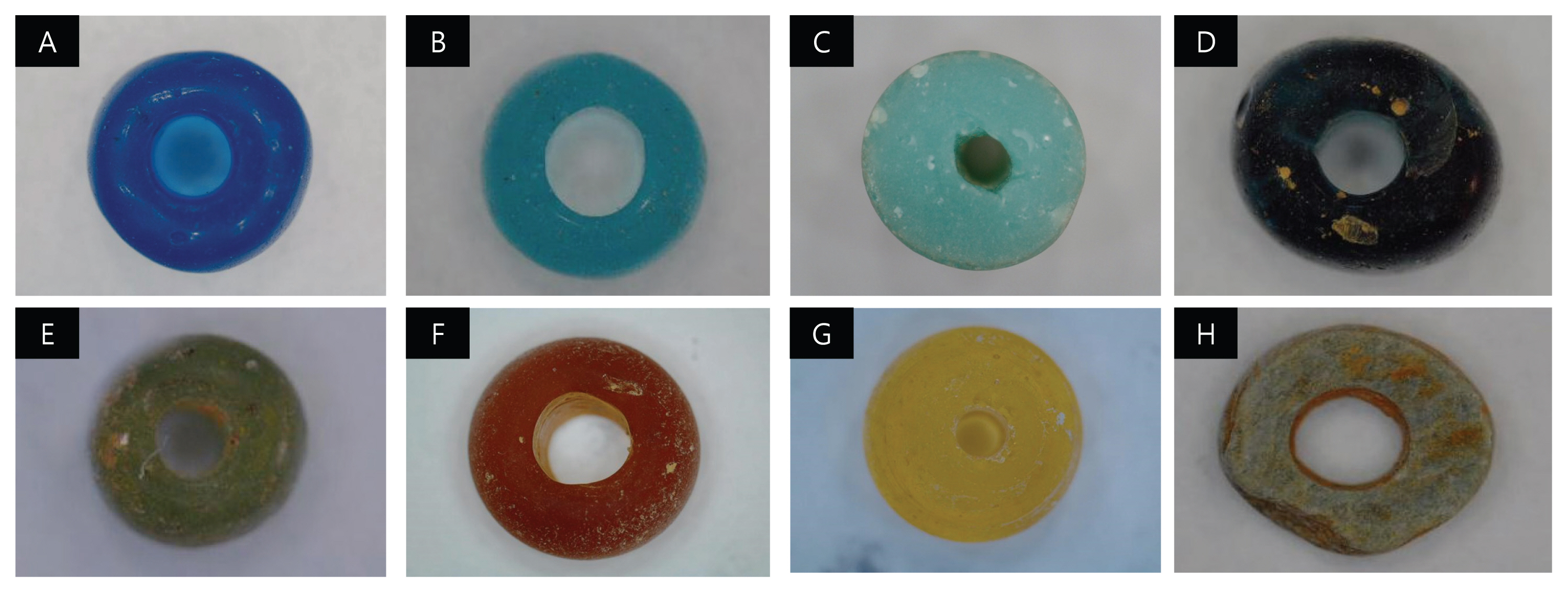

The eight color types of the beads are identified and classified as consisting of 19 cobalt blue beads, 6 copper blue beads, 1 greenish blue bead, 1 Blueeish green bead, 1 green bead, 6 brown beads, 2 lemon yellow beads, and 1 gray bead. The bead colors vary depending on the period: blue colors, such as cobalt blue and copper blue, correspond to the Proto-Three Kingdoms and Three Kingdoms periods, while brown and lemon yellow beads correspond to the Joseon Dynasty (Figure 6). The gray color is determined to be a mineral bead.

Glass bead colors from Naedeok-ri site, Gimhae. (A) Co-Blue, (B) Cu-Blue, (C) Greenish Blue, (D) Blueish Green, (E) Green, (F) Brown, (G) Lemon Yellow, (H) Gray.

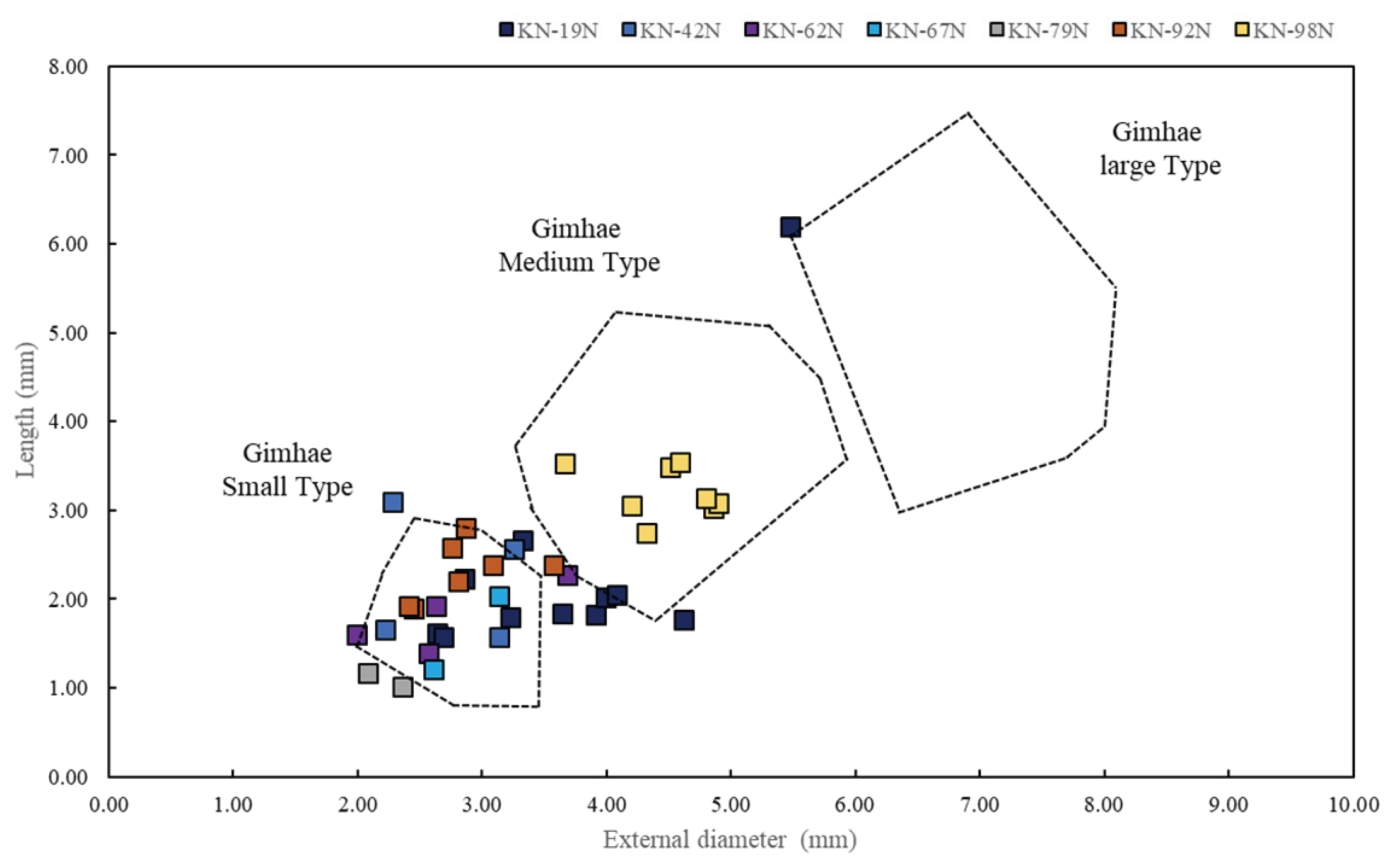

The heat treatment technique is used to verify whether the beads had been appropriately molded after fabrication, which appears to generally be the case. Traces of polishing are identified in the long tubular beads (KN-19N-01) and mineral beads (KN-67N-02). Although the surface conditions of the beads may have been generally good, some beads showed surface weathering or cracks; thus, limited data is expected from surface analysis. The production technique is judged to be a stretching technique if any stripe or bubble arrangement matches the direction of the inner diameter, a drawn technique if there are stripes in the vertical direction of the inner diameter, and a winding technique if there are stripes parallel to the inner diameter. According to the classification results, the glass bead production techniques used in Naedeok-ri Gimhae varied depending on the period. Folding and drawing, winding techniques are found in remains created during the Proto-Three Kingdoms period, the Three Kingdoms period, and the Joseon Dynasty, respectively. The bead sizes are compared by referring to the previously determined size classification data of 129 pieces from the Geumgwan Gaya region. The sizes of Geumgwan Gaya glass beads are divided into three categories based on the outer diameter: Gimhae small-sized, 2.9±0.4 mm, Gimhae medium-sized, 4.8±0.6 mm, and Gimhae large-sized, 7.0±0.7 mm (Kim et al., 2021). The sizes of glass beads from Naedeok-ri, Gimhae, are identified as 21 small-sized, 8 medium-sized, and 1 large-sized, with 7 unclassified between small- and medium-sized beads. Depending on the period, glass beads from Naedeok-ri, Gimhae are divided into small- and large-sized beads from the Proto-Three Kingdoms and Three Kingdoms periods, and medium-sized beads from the Joseon Dynasty. Considering all Gaya remains, small-sized beads were popular during the Proto-Three Kingdoms and Early Gaya periods, while medium-sized beads became widely accepted during the later Gaya period. Small-sized beads appear to have been popular in Naedeok-ri, Gimhae, until the late Gaya period, and the size of one tubular-shaped bead (KN-19N-01) is confirmed to equal that of the beads from the Proto-Three Kingdoms period (Kim, 2023).

4.4. Surface Composition

The non-destructive analysis results of 38 round glass beads excavated from Naedeok-ri, Gimhae, and their classification results according to composition are described as follows (Table 7, Figure 8).

Classification results on the chemical composition of glass beads from the Naedeok-ri site, Gimhae. (A) fluxes, (B) expand fluxes, (C) potash stabilizer, (D) Soda stabilizer.

According to the classification results of the flux characteristics of Naedeok-ri glass beads, there are 3, 28, 5, 1, and 1 beads consisting of lead glass, potash glass, soda glass, mineral, and unclassified groups, respectively.

The components of the lead glass group vary depending on the era. These include one lead-barium glass bead (KN-19N-01) in which barium (Ba) is detected, which was excavated among remains from the 2nd century, and two lead glass beads in which only lead (Pb) is detected. They were excavated from the remains of the Joseon Dynasty (KN-98N-07, 08). Regarding the stabilizer characteristics, lead-barium glass beads are found to contain 0.97% lime (CaO) and 2.66% alumina (Al2O3). Therefore, with lime being less than 2% corresponding to lead-barium type II, these are identified as from before the 3rd century CE. Converting the detected elements into the ratio of silicon oxide (SiO2) and lead oxide (PbO), it is estimated that the two lead glass beads from the Joseon Dynasty were made with an average ratio of silicon to lead of 60:40. In the case of leaded glass, it is made of 60:40 and exists as a composition value (Kim, 2023).

The potash glass group is divided based on the type of added stabilizers into potash type I with 13 beads, potash type II with 9 beads, and potash type III with 6 beads. The stabilizer composition of potash type I is lime (CaO) and alumina (Al2O3) of less than 3%, of which all the beads are cobalt blue and are excavated from wooden coffin tomb No. 19, which was constructed in the 2nd century. The sample analysis showed the same results, indicating that potash type I had been used until the 4th century. Five cobalt blue and four copper blue beads corresponded to the potash type II group, showing a composition of 3% or more of alumina (Al2O3). Emerald blue beads showed a visible characteristic of a large amount of internal bubbles, which appears to result from the addition of alumina at the time of production. The cross section analysis identified all the beads from Tomb No. 92 as potash type I, while the surface analysis classified all except one as potash type II. During the 4th century, the stabilizer components of the cobalt blue beads varied. Potash Type III was found in remains No. 98 from the Joseon Dynasty, with stabilizer components of lime (CaO) and alumina (Al2O3) of 5% or more. This glass composition is typically found in beads from the Goryeo and Joseon Dynasties. Although this investigation separated the samples into dark brown and brown, there is only a difference in the content of iron oxide (Fe2O3), a glass colorant, and the remaining components are the same.

The soda glass group consists of four beads from No. 62 and one bead from No. 67, all created in the 4th century. These exist in various colors, such as copper blue, green, and turquoise. The stabilizer component is determined to be soda alumina with an alumina content of 5% or more.

The mineral beads are gray and are excavated from 5th-century remains. They contain 55.88% of silicon oxide (SiO2) and 10.63% of magnesium oxide (MgO), which is considered to be talc. The chemical formula of talc is Mg3Si4O10(OH)2 and it have the lowest hardness of 1 on the Mohs scale of mineral hardness. Its softness allows drilling and facilitates the production of beads.

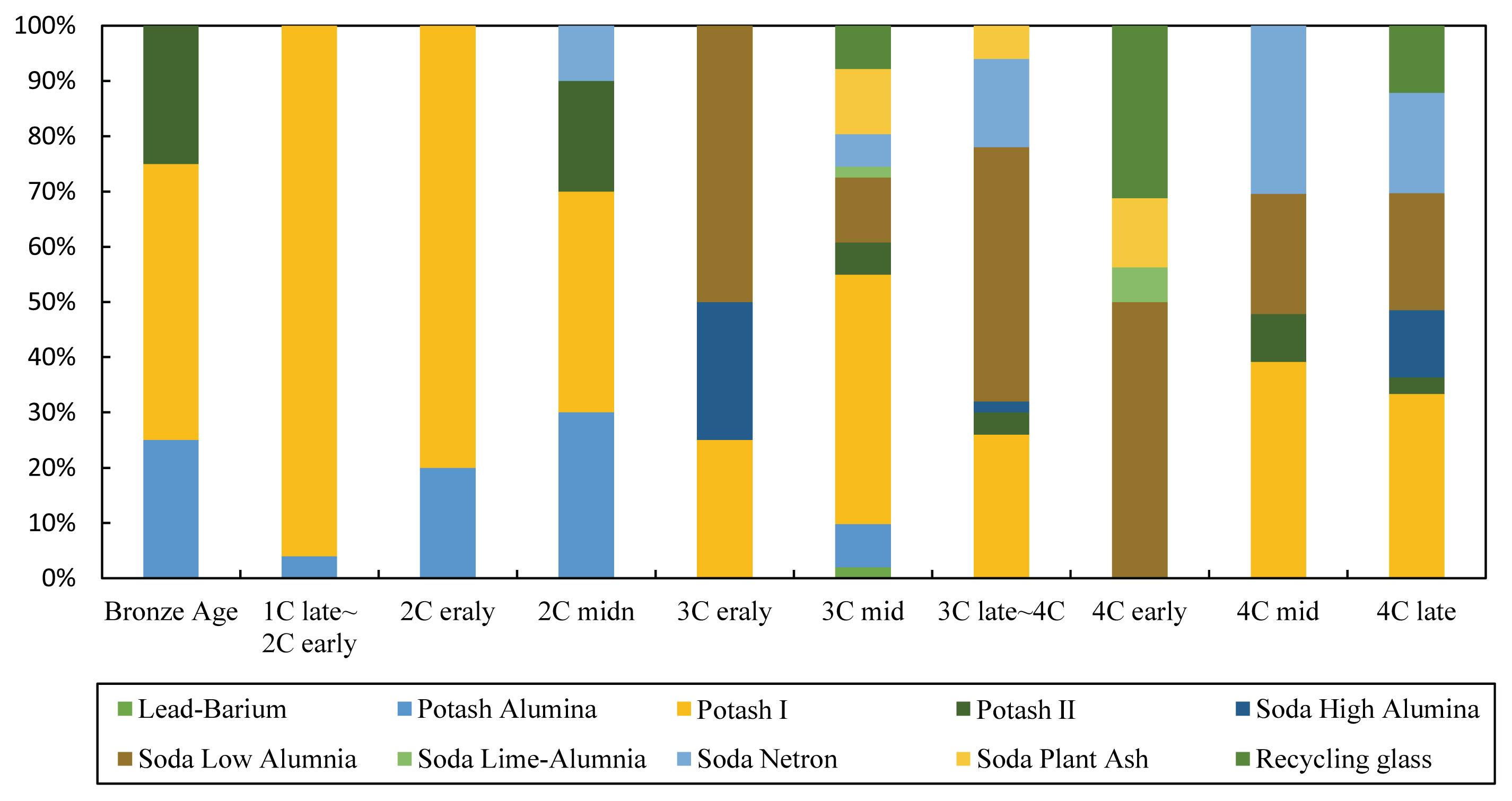

This study examines the characteristics of remains by comparing surface analysis results of glass beads from Naedeok-ri, Gimhae, with the chemical compositions of beads from the Gimhae region (Figure 9). In Naedeok-ri, Gimhae, lead-barium glass beads appear during the Proto-Three Kingdoms period. In Naedeok-ri, Gimhae, only potash glass beads are identified as originating during the early Gaya period, and soda glass beads are found from the later Gaya period. However, compared with other remains in Gimhae, the absence of potash glass and the high proportion of soda suggest that Naedeok-ri, Gimhae, is influenced by Silla rather than Gaya in the 5th century. As Naedeok-ri in Gimhae entered the Joseon Dynasty, its glass beads exhibit different compositional characteristics from those of the previous Proto-Three Kingdoms and Three Kingdoms periods.

5. CONCLUSION

This study examines the characteristics of ancient glass beads from the Gimhae region through scientific analysis of 48 glass beads excavated from the Naedeok-ri site in Gimhae. It analyzed the cross-sectional characteristics and chemical composition of 10 broken fragments to survey the tendency of the remains and selected 38 round beads using HH-XRF to examine the characteristics of these remains. According to the cross section analysis results of the broken beads, all the beads are determined to be potash type I and revealed a pattern that the beads from Naedeok-ri, Gimhae, adhered to using potash glass during the Proto-Three Kingdoms and the early Gaya periods. According to the surface analysis results on the round beads, there are 3, 28, 5, 1, and 1 beads classified into the lead glass, potash glass, soda glass, mineral, and unclassified groups, respectively. The Naedeok-ri site in Gimhae demonstrates that glass beads with various components are available and underwent changes in compositions in the following order: lead-barium II → potash I·II → soda alumina → potash III·lead. Compared with previous research results from the Gimhae area, the Naedeok-ri site is the first to show the use of lead-barium glass in Gimhae. Potash glass was exclusively used until the early Gaya period, and Potash glass beads were replaced with soda glass beads around Naedeok-ri, Gimhae during the late Gaya period when Goguryeo’s expedition began and Geumgwan Gaya declined. This is distinct from other regions in Gimhae where potash glass had been exclusively used. This study presents a research method that can reveal the characteristics of glass beads excavated from remains in the future that utilizes the advantages of sample analysis and non-destructive analysis methods. If data are accumulated by period and region in the future, the results of this study will provide basic data that will allow the determination of when glass is used and where it was imported to on the Korean Peninsula.

ACKNOWLEDGMENTS

This study was conducted on a research scholarship from the National Research Foundation of the Korea Preservation Research Support Project (Ministry of Education) in 2023. (No. NRF-2021R1I1A2040339).