|

|

- Search

| J. Conserv. Sci > Volume 35(6); 2019 > Article |

|

мҙҲ лЎқ

ліё м—°кө¬лҠ” м „нҶөм ңмІ лІ•мқё м •л Ё л°Ҹ лӢЁм ‘мқ„ м Ғмҡ©н•ң мӮ¬мІ к°•кҙҙ(SI)мқҳ лҜём„ёмЎ°м§Ғмқ„ нҢҢкҙҙ분м„қлІ•мқё нҳ„лҜёкІҪ분м„қкіј 비нҢҢкҙҙ분м„қлІ•мқё мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ нҶөн•ҙ 분м„қкІ°кіјлҘј 비көҗн•ҳмҳҖлӢӨ. мӢңлЈҢлҠ” м „нҶөм ңмІ лІ•мңјлЎң мғқмӮ°н•ң мӮ¬мІ к°•кҙҙмқҙл©°, нҢҢкҙҙ분м„қмҡ©мқҳ SI-AмҷҖ 비нҢҢкҙҙ분м„қмҡ©мқҳ 9 cm2мқҳ SI-BлҘј м ңмһ‘н•ҳмҳҖлӢӨ. нҢҢкҙҙ분м„қмңјлЎң кёҲмҶҚнҳ„лҜёкІҪкіј мЈјмӮ¬м „мһҗнҳ„лҜёкІҪмқҙ мқҙмҡ©лҗҳм—Ҳмңјл©°, 비нҢҢкҙҙ분м„қмңјлЎң мқјліё нӣ—м№ҙмқҙлҸ„ лҢҖн•ҷмқҳ мҶҢнҳ• мӨ‘м„ұмһҗмӣҗ мқҙмҡ©мӢңм„Өмқ„ нҶөн•ң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мқҙмҡ©н•ҳмҳҖлӢӨ. нҢҢкҙҙ분м„қкІ°кіј лҜём„ён•ң ferrite л°Ҹ pearliteк°Җ, мӢңлЈҢмқҳ к°ҖмһҘмһҗлҰ¬м—җм„ң WidmanstГӨtten ferriteмҷҖ мЎ°лҢҖн•ң ferriteк°Җ кҙҖм°°лҗҳм—ҲлӢӨ. лҳҗн•ң 비нҢҢкҙҙ분м„қлІ•мқё мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қ кІ°кіј мІҙмӢ¬мһ…л°©кІ©мһҗ кө¬мЎ°мқҳ grain sizeк°Җ 3 Ојm м •лҸ„мқҳ Оұ-Feмқё ferriteмҷҖ мёөмғҒмқҳ pearliteк°Җ кҙҖм°°лҗҳм—ҲлӢӨ. мқҙл Үл“Ҝ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мқҙмҡ©н•ҳл©ҙ 비нҢҢкҙҙлЎң м—°кө¬лҢҖмғҒмқҳ мһ¬лЈҢкіјн•ҷм Ғ нҠ№м„ұмқ„ нҷ•мқён• мҲҳ мһҲкі л¬ёнҷ”мһ¬м—җ м Ғмҡ© мӢң мөңм Ғмқҳ м—°кө¬кІ°кіјлҘј м–»мқ„ мҲҳ мһҲмқҢмқ„ нҷ•мқён•ҳмҳҖлӢӨ.

ABSTRACT

The purpose of this study was to compare analytical results of sand iron bars reproduced by the traditional iron-making method through a destructive analysis and a non-destructive analysis. For these studies, we produced two types of samples. One was sample(SI-A), a part of the sand iron bar for destructive analysis. The other was SI-B(9 cm2) for non-destructive analysis. A metallurgical microscope and scanning electron microscope were used for the destructive analysis, and neutron imaging analysis with the Hokkaido University Neutron Source (HUNS) at Hokkaido University, Japan, was used for the non-destructive analysis. The results obtained by destructive analysis showed that there was ferrite and pearlite of fine crystallite size, and some of these showed WidmanstГӨtten ferrite microstructure grown within the pearlite and coarse ferrite at the edge of the specimen. The results from the neutron imaging analysis showed that there was also ferrite and pearlite with 3 Ојm Оұ-Fe of BCC structure. Based on these results, neutron imaging analysis is capable of identifying material characteristics without destroying the object and obtaining optimal research results when applying it to objects of cultural heritage.

кі лҢҖ н•ңл°ҳлҸ„ көӯк°Җмқё мӢ лқј(ж–°зҫ…), к°Җм•ј(дјҪиҖ¶), л°ұм ң(зҷҫжҝҹ)мқҳ мЈјмҡ”н•ң м ңмІ лІ•мқҖ м§Ғм ‘м ңл ЁлІ•(зӣҙжҺҘиЈҪйҚҠжі•)мңјлЎң мқҙлҘј нҶөн•ҙ лӢӨм–‘н•ң мІ л¬јмқ„ м ңмһ‘н•ҳмҳҖлӢӨ. м§Ғм ‘м ңл ЁлІ•мқҖ мІ кҙ‘м„қ нҳ№мқҖ мӮ¬мІ мқ„ м ңл ЁлЎңм—җм„ң м ңл Ён•ҳм—¬ кҙҙл ЁмІ мқ„ мғқмӮ°н•ҳлҠ” л°©мӢқмңјлЎң, м§Ғм ‘м ңл ЁлІ•мңјлЎң мғқмӮ°лҗң кҙҙл ЁмІ мқҖ лӢӨлҹүмқҳ л¶ҲмҲңл¬јмқҙ мЎҙмһ¬н•ҳкё° л•Ңл¬ём—җ к°•лҸ„к°Җ л–Ём–ҙм ё мІ л¬јлЎң мӮ¬мҡ©мқҙ л¶Ҳк°ҖлҠҘн•ҳлӢӨ. к·ёлҹ¬лҜҖлЎң кҙҙл ЁмІ лӮҙл¶Җмқҳ л¶ҲмҲңл¬јмқ„ м ңкұ°н•ҳкі к°•лҸ„лҘј н–ҘмғҒмӢңнӮӨкё° мң„н•ҙ м •л Ёкіј лӢЁмЎ° кіөм •мқҖ н•„мҲҳм ҒмқҙлӢӨ. мқҙлҹ¬н•ң кіөм •мқ„ кұ°міҗ лӮҙл¶Җмқҳ л¶ҲмҲңл¬јмқҙ м ңкұ°лҗҳкі , кіөк·№мқҙ мӨ„м–ҙл“ к°•кҙҙк°Җ мғқмӮ°лҗңлӢӨ. мқҙмІҳлҹј м§Ғм ‘м ңл ЁлІ•мқҖ м ңл Ёмқ„ нҶөн•ҙ кҙҙл ЁмІ мқ„ мғқмӮ°н•ҳкі , лӢӨмӢң м •л Ё л°Ҹ лӢЁм ‘кіөм •мқ„ нҶөн•ҙ мөңмў…м Ғмқё к°•кҙҙлҘј мғқмӮ°н•ҳлҠ” кі лҢҖ м ңл ЁлІ•мқҳ н•ң мў…лҘҳмқҙлӢӨ.

м§Ғм ‘м ңл ЁлІ•мқҳ кі лҢҖ м ңмІ лІ•мңјлЎң мғқмӮ°лҗң к°•кҙҙлҠ” лӢЁмЎ° кіөм •мңјлЎң мқён•ҙ лӢӨлҘё м ңл ЁлІ•м—җ 비н•ҙ мғҒлӢ№нһҲ лҜём„ён•ң кёҲмҶҚмЎ°м§Ғмқ„ ліҙмқёлӢӨ. лҳҗн•ң кіөм • кіјм •м—җм„ң к°Җкіөмқҳ нҺёлҰ¬м„ұкіј м ‘н•©мқҳ мҡ©мқҙм„ұмқ„ н–ҘмғҒмӢңнӮӨкё° мң„н•ҙ к°•кҙҙлҘј к°Җм—ҙн•ҳкІҢ лҗҳкі , лӢЁм ‘кіөм •м—җм„ң м№Ёнғ„мқҙ 진н–үлҗңлӢӨ. мқҙнӣ„ к°Җм—ҙлҗң к°•кҙҙлҠ” кіөкё° мӨ‘м—җм„ң м„ңм„ңнһҲ лғүк°Ғлҗҳл©ҙм„ң кёҲмҶҚмЎ°м§ҒмқҖ мқјл°ҳм ҒмңјлЎң нҺҳлқјмқҙнҠё(ferrite)мҷҖ мӢңл©ҳнғҖмқҙнҠё(cementite)к°Җ мёөмғҒмқ„ мқҙлЈЁлҠ” нҺ„лқјмқҙнҠё(pearlite)лҘј нҳ•м„ұн•ҳкІҢ лҗңлӢӨ.

мқҙлҹ¬н•ң кёҲмҶҚмЎ°м§ҒмқҖ мқјл°ҳм ҒмңјлЎң кёҲмҶҚнҳ„лҜёкІҪкіј мЈјмӮ¬м „мһҗнҳ„лҜёкІҪ(Scanning electron microscope, SEM) 분м„қмқ„ нҶөн•ҙ нҷ•мқёмқҙ к°ҖлҠҘн•ҳл©°, м§Ғм ‘м ңл ЁлІ•мңјлЎң м ңмһ‘лҗң к°•кҙҙлҠ” мғҒлӢ№нһҲ лҜём„ён•ң нҺ„лқјмқҙнҠё(pearlite) мЎ°м§Ғмқ„ к°Җм§Җкі мһҲлҠ” кІғмқ„ нҷ•мқён• мҲҳ мһҲлӢӨ. н•ҳм§Җл§Ң кёҲмҶҚнҳ„лҜёкІҪкіј SEMмқ„ мқҙмҡ©н•ң 분м„қ л°©лІ•мқҖ 2к°Җм§Җмқҳ лӢЁм җмқ„ к°Җм§Җкі мһҲлӢӨ. мІ« лІҲм§ё лӢЁм җмқҖ 분м„қмқ„ мң„н•ҙ мӢңлЈҢмқҳ м ҲлӢЁ, м—°л§ҲмҷҖ к°ҷмқҖ м „мІҳлҰ¬к°Җ н•„мҲҳм ҒмқҙлӢӨ. мқјл°ҳм ҒмңјлЎң мһ‘мқҖ мӢңлЈҢмҷҖ л§ӨлҒ„лҹ¬мҡҙ мң лҰ¬л©ҙл§Ң 분м„қмқҙ к°ҖлҠҘн•ҳкё° л•Ңл¬ём—җ мӢңлЈҢмқҳ мӣҗнҳ•ліҙмЎҙмқҙ нһҳл“ӨлӢӨ. к·ёлҹ¬лҜҖлЎң мқҙлҹ¬н•ң л°©мӢқмқҖ л¬ёнҷ”мһ¬м—җ м Ғмҡ©н•ҳкё° мң„н•ҙм„ңлҠ” кі л Өн•ҙн• кІғмқҙ л§ҺлӢӨ. л‘җ лІҲм§ё лӢЁм җмқҖ мӢңлЈҢ лӘЁл“ мҳҒм—ӯмқҳ 분м„қмқҙ мүҪм§Җ м•ҠлӢӨ. кёҲмҶҚнҳ„лҜёкІҪкіј SEM 분м„қлІ•мқҖ мӢңлЈҢлҘј 1,000л°°(кёҲмҶҚнҳ„лҜёкІҪ) нҳ№мқҖ мҲҳмӢӯл§Ң л°°(SEM)к№Ңм§Җ нҷ•лҢҖн•ҙм„ң кҙҖм°°н•ҳкё° л•Ңл¬ём—җ н•ң лІҲм—җ кҙҖм°° к°ҖлҠҘн•ң мҳҒм—ӯмқҖ 1 mmк°Җ лҗҳм§Җ м•ҠлҠ”лӢӨ. к·ёлҹ¬лҜҖлЎң кёҲмҶҚнҳ„лҜёкІҪкіј SEMмңјлЎң кҙҖм°°н•ң мқјл¶Җ분мңјлЎң мӢңлЈҢмқҳ лӘЁл“ мҳҒм—ӯмқ„ мң 추н•ҙм•ј н•ңлӢӨ. мқҙлҹҙ кІҪмҡ°, лӘЁл“ мҳҒм—ӯмқҳ нҠ№м„ұмқҙ мҷңкіЎлҗҳлҠ” нҳ„мғҒмқҙ л°ңмғқн• мҲҳлҸ„ мһҲлӢӨ.

к·ёлҹ¬лҜҖлЎң ліё м—°кө¬м—җм„ңлҠ” 비нҢҢкҙҙм ҒмңјлЎң мӢңлЈҢмқҳ лӘЁл“ мҳҒм—ӯм—җ лҢҖн•ң 분м„қмқҙ к°ҖлҠҘн•ң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ нҷңмҡ©н•ҳмҳҖлӢӨ. м§Ғм ‘м ңл ЁлІ•мңјлЎң мӮ¬мІ к°•кҙҙлҘј м ңмһ‘н•ҳкі , м ңмһ‘лҗң мӮ¬мІ к°•кҙҙ мқјл¶Җ нҠ№м„ұмқҙ м•„лӢҢ лӘЁл“ мҳҒм—ӯм—җ лҢҖн•ң кёҲмҶҚн•ҷм Ғ нҠ№м„ұмқ„ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмңјлЎң лҸ„м¶ңн•ҳкі мһҗ н•ҳмҳҖлӢӨ. к·ёлҰ¬кі мқјл°ҳм Ғмқё кёҲмҶҚнҠ№м„ұ 분м„қм—җ нҷңмҡ©н•ҳлҠ” кёҲмҶҚнҳ„лҜёкІҪ нҳ№мқҖ SEM кё°лІ•мңјлЎң 분м„қн•ң кІ°кіјмҷҖ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қ кІ°кіјлҘј 비көҗн•ҳм—¬ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқҳ мң нҡЁм„ұмқ„ кІҖмҰқн•ҳкі , мөңмў…м ҒмңјлЎң 비нҢҢкҙҙ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ л¬ёнҷ”мһ¬ м Ғмҡ© к°ҖлҠҘм„ұмқ„ нҷ•мқён•ҳмҳҖлӢӨ.

мӨ‘м„ұмһҗлҘј нҷңмҡ©н•ң лҢҖн‘ңм Ғмқё көӯлӮҙ м—°кө¬ мӮ¬лЎҖлҠ” 2003л…„м—җ кіјн•ҷкё°мҲ л¶Җ(зҸҫ кіјн•ҷкё°мҲ м •ліҙнҶөмӢ л¶Җ)мқҳ мӣҗмһҗл Ҙм—°кө¬к°ңл°ңмӮ¬м—…мңјлЎң мҲҳн–үн•ң вҖҳмӨ‘м„ұмһҗ л Ҳл””мҳӨк·ёлқјн”јлҘј мқҙмҡ©н•ң мң л¬ј 분м„қкё°мҲ к°ңл°ңвҖҷмқ„ нҶөн•ҙ көӯлӮҙм—җм„ң л¬ёнҷ”мһ¬м—җ м Ғмҡ©н•ң м—°кө¬к°Җ мӢңмһ‘лҗҳм—ҲлӢӨ. лӢ№мӢң м—°кө¬лҠ” л§ӨмһҘ кёҲмҶҚл¬ёнҷ”мһ¬мқҳ м„ұ분 분м„қ л°Ҹ лӮҙл¶Җкө¬мЎ° мҳҒмғҒнҷ”лҘј мң„н•ң 비нҢҢкҙҙ мЎ°мӮ¬л°©лІ•м—җ кҙҖн•ң м—°кө¬лЎңмҚЁ, мӨ‘м„ұмһҗ л°©мӮ¬нҷ” 분м„қкіј мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ нҷңмҡ©н•ҳмҳҖлӢӨ. м—°кө¬м—җ мӮ¬мҡ©лҗң мӢңлЈҢлҠ” 충лӮЁ мІңм•ҲмӢңмқҳ мҡ©мӣҗлҰ¬ кі л¶„кө°мқҳ м„қкіҪл¬ҳ л°Ҹ нҶ кҙ‘л¬ҳм—җм„ң м¶ңнҶ лҗң мІ м ң нҷҳл‘җлҢҖлҸ„, м°Ҫ л°Ҹ мІ лӘЁ л°Ҹ мІ л¶Җ л“ұмқ„ лҢҖмғҒмңјлЎң н•ҳмҳҖлӢӨ(Ministry of Science and Technology, 2004). н•ҙлӢ№ м—°кө¬м—җм„ңлҠ” мӨ‘м„ұмһҗ л°©мӮ¬нҷ” 분м„қмңјлЎң л§ӨмһҘ кёҲмҶҚл¬ёнҷ”мһ¬мқҳ м„ұ분 분м„қмқ„ мҲҳн–үн•ҳмҳҖм§Җл§Ң, лӢ№мӢң көӯлӮҙ кё°мҲ мқҳ лҜёл№„лЎң мқён•ҳм—¬ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмңјлЎңлҠ” лӢЁмҲңнһҲ мң л¬ј лӮҙл¶Җл§Ң кҙҖм°°н•ҳмҳҖлӢӨ.

мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқҖ көӯлӮҙліҙлӢӨлҠ” н•ҙмҷём—җм„ң нҷңл°ңн•ҳкІҢ нҷңмҡ©лҗҳкі мһҲмңјл©°, л§ҺмқҖ мӮ¬лЎҖлҘј нҷ•мқён• мҲҳ мһҲлӢӨ. нҠ№нһҲ мөңк·ј м§Җм—ӯм—җ л”°лҘё мқјліёлҸ„мқҳ м ңмһ‘ кё°лІ• 분м„қмқ„ мң„н•ҙ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мӮ¬мҡ©лҗҳм—ҲлӢӨ. к·ё мӨ‘м—җм„ңлҸ„ мқјліё нӣ—м№ҙмқҙлҸ„(Hokkaido) лҢҖн•ҷмқҳ Nagashima көҗмҲҳлҠ” нӣ—м№ҙмқҙлҸ„ лҢҖн•ҷмқҳ мҶҢнҳ• мӨ‘м„ұмһҗмӣҗ мқҙмҡ©мӢңм„Өмқё HUNS (Hokkaido University Neutron Source)мҷҖ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қлІ•мқ„ мқҙмҡ©н•ҳм—¬ 2м җмқҳ мқјліёлҸ„лҘј 분м„қн•ҳмҳҖлӢӨ(Nagashima et al., 2014). н•ҙлӢ№ л…јл¬ём—җм„ңлҠ” мӨ‘м„ұмһҗ мҳҒмғҒ, нҠ№нһҲ к°ҷмқҖ л¬јм§ҲмқҙлқјлҸ„ нҢҢмһҘм—җ л”°лқј лӢӨлҘё мӨ‘м„ұмһҗ нҲ¬кіј нҠ№м„ұ(Bregg-edge)мқ„ нҷңмҡ©н•ҳм—¬ мӢңлЈҢлі„, мӢңлЈҢмқҳ мң„м№ҳм—җ л”°лҘё кІ°м •м„ұ мқҙл°©м„ұ(crystallographic anisotropy)кіј кІ°м •мқҳ нҒ¬кё°(crystallite size)лҘј кҙҖм°°н•ҳмҳҖлӢӨ. мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қкІ°кіј, к°Ғ 분м„қлҗң мӢңлЈҢл§ҲлӢӨ кІ°м •мқҳ нҒ¬кё°к°Җ лӢӨлҘҙл©°, 비лЎқ к°ҷмқҖ мӢңлЈҢлқјлҸ„ мң„м№ҳм—җ л”°лқј(м№јмқҳ м№јлӮ л¶Җ분과 м№јл“ұл¶Җ분) кІ°м •нҒ¬кё°лҸ„ лӢӨлҘҙлӢӨлҠ” кІғмқ„ м—ӯмӢң нҷ•мқён•ҳмҳҖлӢӨ. лҳҗн•ң мқҙ кІ°кіјлҘј нҶ лҢҖлЎң м ңмһ‘ кё°лІ•мқҙ лӢӨлҘё 2м җмқҳ мқјліёлҸ„м—җ лҢҖн•ң кІ°м •н•ҷм Ғ нҠ№м„ұмқ„ нҷ•мқён•ҳкі , м ңмһ‘ кё°лІ•м—җ л”°лқј к·ё нҠ№м„ұмқҙ м„ңлЎң лӢӨлҘҙлӢӨлҠ” кІғмқ„ лҸ„м¶ңн•ҳмҳҖлӢӨ. лҚ”л¶Ҳм–ҙ мӣҗмһҗлЎңм—җ 비н•ҙ мӨ‘м„ұмһҗ мҶҚлҸ„к°Җ лӮ®мқҖ к°ҖмҶҚкё° кё°л°ҳ мҶҢнҳ• мӨ‘м„ұмһҗ мқҙмҡ© мӢңм„ӨлҸ„ л¬ёнҷ”мһ¬ 분м„қм—җ нҷңмҡ© к°ҖлҠҘн•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ(Nagashima et al., 2014).

мқҙмҷём—җлҸ„ мӨ‘м„ұмһҗлҘј мқҙмҡ©н•ң лӢӨм–‘н•ң м—°кө¬л…јл¬ёмқҙ мЎҙмһ¬н•ҳл©°, нҠ№нһҲ л¬ёнҷ”мһ¬м—җ м Ғмҡ©н•ң мӮ¬лЎҖк°Җ л§ҺлӢӨ. мқҙмІҳлҹј н•ҙмҷём—җм„ңлҠ” мӨ‘м„ұмһҗлҘј мқҙмҡ©н•ҙ л¬ёнҷ”мһ¬ 분м„қмқ„ нҷңл°ңнһҲ мӢӨмӢңн•ҳкі мһҲмңјл©°, лҳҗн•ң 비нҢҢкҙҙм ҒмңјлЎң м—°кө¬мһҗк°Җ мӣҗн•ҳлҠ” кІ°кіјлҘј м–»мқ„ мҲҳ мһҲлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ.

мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қм—җ мӮ¬мҡ©лҗң мӮ¬мІ к°•кҙҙлҠ” 2018л…„м—җ 진н–үлҗң кі лҢҖ м „нҶөм ңмІ лІ•мқҳ мһ¬нҳ„мӢӨн—ҳмқ„ нҶөн•ҙ мғқмӮ°лҗҳм—Ҳмңјл©°, мӮ¬мІ к°•кҙҙмқҳ м ңмһ‘ л°©лІ•мқҖ лӢӨмқҢкіј к°ҷлӢӨ(Cho, 2015; Cho et al., 2018b;Oh et al., 2018).

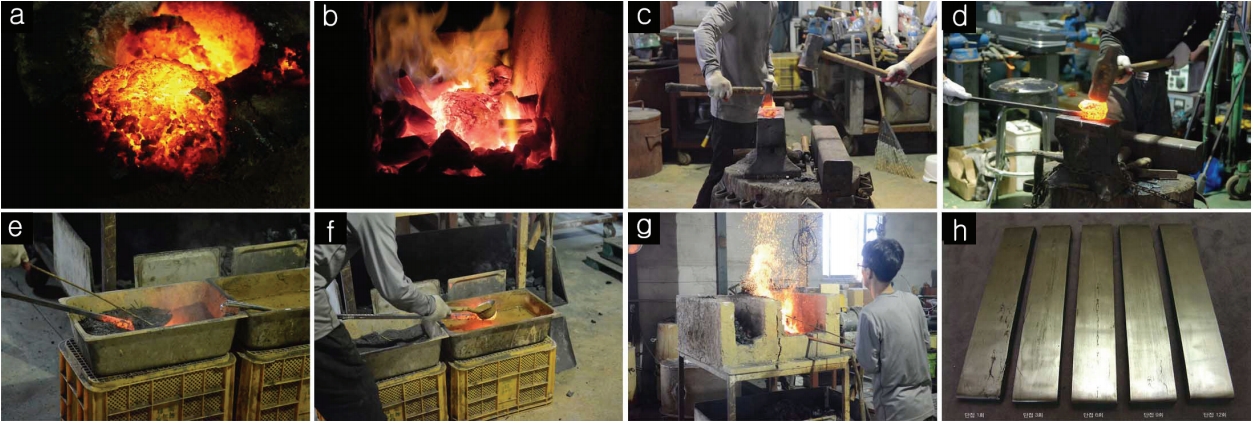

м ңл ЁлЎңлҘј м ңмһ‘н•ҳм—¬ кҙҙл ЁмІ мқ„ мғқмӮ°н•ҳмҳҖлӢӨ. м ңл ЁлЎңлҠ” кі лҢҖ м ңмІ мң м Ғ л°Ҹ кі л¬ён—Ңмқ„ кё°л°ҳмңјлЎң м„Өкі„н•ҳмҳҖлӢӨ. н•ңл°ҳлҸ„м—җм„ң л°ңкІ¬лҗң м ңл ЁлЎңмқҳ лҢҖл¶Җ분мқҖ мӣҗнҳ•мңјлЎң мқҙлЈЁм–ҙм ё мһҲкі , мқјл¶Җ м ңл ЁлЎңм—җм„ң мһҘл°©нҳ•мқҙлӮҳ м„ёмһҘл°©нҳ•мқҙ нҷ•мқёлҗҳм—ҲлӢӨ. нҠ№нһҲ мӣҗнҳ•лЎңмқҳ кІҪмҡ° м§ҒкІҪ 115 cmм—җм„ң 150 cm м •лҸ„мқҳ нҒ¬кё°мқҙл©° мқјл¶ҖлҠ” л°°мһ¬кө¬к°Җ кіөл°ҳлҗң кө¬мЎ°мҳҖлӢӨ. мқҙлҘј нҶ лҢҖлЎң 3лӢЁмқҳ мӣҗнҳ• м ңл ЁлЎңлҘј м„Өкі„н•ҳмҳҖмңјл©°, мӮ¬мҡ©лҗң мһ¬лЈҢлҠ” нҷ©нҶ (й»ғеңҹ), л°ұнҶ (зҷҪеңҹ), м„қнҡҢм„қ(зҹізҒ°зҹі)мқ„ мӮ¬мҡ©н•ҳмҳҖлӢӨ. лҳҗн•ң м ңл ЁлЎңмқҳ н•ҳлӢЁм—җлҠ” мҠ¬лһҳк·ёлҘј л°°м¶ңн•ҳкё° мң„н•ң м§ҒкІҪ 7 cmмқҳ кө¬л©Қмқ„ л§Ңл“Өм—ҲлӢӨ(Cho et al., 2018a).

м ңл Ёмқ„ мң„н•ҙ мҶҢлӮҳл¬ҙ лӘ©нғ„кіј кІҪмЈј мӮ¬мІ мқ„ мқҙмҡ©н•ҳмҳҖлӢӨ. лӘ©нғ„ 20 kgлҘј м ңл ЁлЎңм—җ л„Јкі м—°мҶҢмӢңмјң м ңл ЁлЎңлҘј мҷ„м „ кұҙмЎ°мӢңмј°лӢӨ. мӮ¬мІ 1 kgмҷҖ лӘ©нғ„ 2.5 kgмқ„ м ңл ЁлЎңм—җ нҲ¬мһ…н•ҳкі , н•ҳлӢЁмқҳ л°°м¶ңкө¬лҘј нҶөн•ҙ мҠ¬лһҳк·ёлҘј мЈјкё°м ҒмңјлЎң л°°м¶ңн•ҳмҳҖлӢӨ. мқҙ л•Ң мӮ¬мІ кіј лӘ©нғ„мқҖ 10분 к°„кІ©мңјлЎң л°ҳліөн•ҳм—¬ мҙқ 170 kgмқҳ мӮ¬мІ мқ„ мһҘмһ…н•ҳмҳҖлӢӨ. м ңл Ёмқ„ мң„н•ң мЎ°мһ¬м ңлҠ” мІЁк°Җн•ҳм§Җ м•Ҡм•ҳкі , н•ҳлӢЁмқҳ мҶЎн’Қкө¬лҘј нҶөн•ҙ кё°кі„мҶЎн’Қмқ„ мӢӨмӢңн•ҳмҳҖлӢӨ. м ңл Ёмһ‘м—…мқҙ мҷ„лЈҢлҗң нӣ„ мөңмў…м ҒмңјлЎң Figure 1aмІҳлҹј 22 kgмқҳ кҙҙл ЁмІ мқ„ мғқмӮ°н•ҳмҳҖлӢӨ. м ңл Ёкіөм •мқҖ мҙқ 17мӢңк°„ лҸҷм•Ҳ 진н–үлҗҳм—Ҳмңјл©°, м ңл Ёмқ„ мң„н•ң л…ёмқҳ мһ‘м—…мҳЁлҸ„лҠ” 1,200в„ғлЎң нҷ•мқёлҗҳм—ҲлӢӨ(Cho et al, 2018b).

мғқмӮ°лҗң кҙҙл ЁмІ м—җ м •л Ёкіөм • л°Ҹ лӢЁм ‘кіөм •мқ„ 진н–үн•ҳмҳҖлӢӨ. лӢЁм•јлЎңм—җ мҶҢлӮҳл¬ҙ лӘ©нғ„мқ„ нҲ¬мһ…н•ҳкі , 1,200в„ғлЎң мғҒмҠ№мӢңмј°лӢӨ. мқҙ нӣ„ Figure 1bмІҳлҹј кҙҙл ЁмІ мқ„ лӢЁм•јлЎңм—җ л„Јкі к°Җм—ҙмӢңмјң м •л Ёкіөм • л°Ҹ лӢЁм ‘кіөм •мқ„ мӢӨмӢңн•ҳмҳҖлӢӨ. к°Җм—ҙлҗң кҙҙл ЁмІ лӮҙл¶Җм—җм„ң л¶ҲмҲңл¬јмқҙ м„қм¶ңлҗҳл©ҙ лӘЁлЈЁ мң„м—җм„ң лӢЁмЎ°лҘј н•ҳм—¬ м§ҒмӮ¬к°Ғнҳ• к°•кҙҙлЎң л§Ңл“Өм—ҲлӢӨ. мқҙл•Ң мӮ¬мІ к°•кҙҙлҘј мүҪкІҢ м ‘кё° мң„н•ҙ Figure 1cмҷҖ к°ҷмқҙ мӨ‘м•ҷмқ„ лҸ„лҒјлЎң лЁјм Җ м ‘кё° мҡ©мқҙн•ҳлҸ„лЎқ нҷҲмқ„ лӮё нӣ„ Figure 1dмҷҖ к°ҷмқҙ к°•кҙҙлҘј м ‘м–ҙ лӢЁмЎ°лҘј н•ҳмҳҖлӢӨ. лӢЁмЎ°лҗң мӮ¬мІ к°•кҙҙлҠ” м№Ёнғ„мқ„ мң„н•ҙ мҲҜк°ҖлЈЁмҷҖ ліҸм§ҡмқ„ 1:1мқҳ 비мңЁлЎң нҳјн•©н•ҳм—¬ Figure 1eмҷҖ к°ҷмқҙ н‘ңл©ҙм—җ кі лЈЁ 묻нҳҖмЈјм—ҲлӢӨ. лҳҗн•ң мһ¬к°Җм—ҙмӢң нғҲнғ„мқ„ л°©м§Җн•ҳкё° мң„н•ҙ мҲҜк°ҖлЈЁлҘј 묻нһҢ мӮ¬мІ к°•кҙҙм—җ нҷ©нҶ л¬ј(нҷ©нҶ 1.6 kg мҷҖ л¬ј 10.52 kg)мқ„ Figure 1fмҷҖ к°ҷмқҙ н‘ңл©ҙм—җ лҸ„нҸ¬н•ҳмҳҖлӢӨ. мҲҜк°ҖлЈЁмҷҖ нҷ©нҶ л¬јмқ„ л°”лҘё к°•кҙҙлҠ” Figure 1gмҷҖ к°ҷмқҙ лӢӨмӢң лӢЁм•јлЎңм—җ л„Јм–ҙ к°Җм—ҙн•ҳкі , 3분м—җм„ң 10분 к°„кІ©мңјлЎң мӮ¬мІ к°•кҙҙлҘј кәјлӮҙм–ҙ лӢЁм ‘мқ„ мӢңн–үн•ҳмҳҖлӢӨ. мҲҜк°ҖлЈЁмҷҖ нҷ©нҶ л¬јмқ„ л°”лҘҙлҠ” кіјм • л°Ҹ мһ¬к°Җм—ҙ, лӢЁм ‘кіөм •мқҖ 10нҡҢ мқҙмғҒ л°ҳліөн•ҳм—¬ м •л Ёкіөм • л°Ҹ лӢЁм ‘кіөм •мқ„ 진н–үн•ҳмҳҖлӢӨ. м •л Ёкіөм • л°Ҹ лӢЁм ‘кіөм •мқҙ л§Ҳл¬ҙлҰ¬лҗҳл©ҙ мөңмў…м ҒмңјлЎң Figure 1hм—җ ліҙмқҙлҠ” мӮ¬мІ к°•кҙҙк°Җ мғқмӮ°лҗңлӢӨ(Cho, 2015;Oh et al, 2018)(Figure 1).

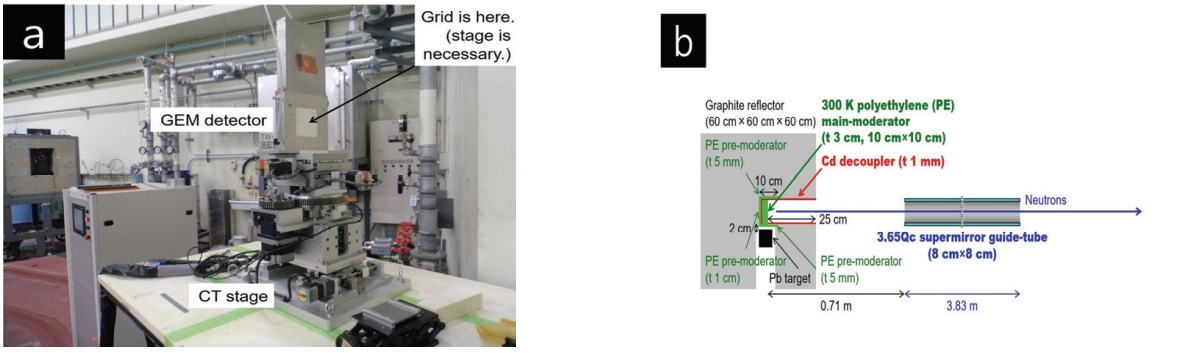

м—°кө¬мҡ© мӣҗмһҗлЎң н•ҳлӮҳлЎңлҠ” көӯлӮҙм—җм„ң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқҙ к°ҖлҠҘн•ң мң мқјн•ң мӨ‘м„ұмһҗ мқҙмҡ©мӢңм„ӨмқҙлӢӨ. м—°кө¬мҡ© мӣҗмһҗлЎңлҠ” н•ө분м—ҙмӢң л°ңмғқн•ҳлҠ” лҶ’мқҖ м—җл„Ҳм§Җмқҳ кі мҶҚмӨ‘м„ұмһҗлҘј м—ҙмӨ‘м„ұмһҗ лҳҗлҠ” лғүмӨ‘м„ұмһҗлЎң к°җмҶҚмӢңмјң мӮ¬мҡ©н•ҳлҠ” мӨ‘м„ұмһҗ мқҙмҡ©мӢңм„ӨлЎңм„ң 1014 n/cm2вӢ…secмқҳ лҶ’мқҖ мӨ‘м„ұмһҗмҶҚмқ„ мқҙмҡ©н• мҲҳ мһҲлӢӨлҠ” мһҘм җмқҙ мһҲлӢӨ. н•ҳлӮҳлЎңмқҳ мӨ‘м„ұмһҗ нҲ¬кіјл№„нҢҢкҙҙкІҖмӮ¬мһҘм№ҳ(Neutron radiography facility, NRF)лҘј мқҙмҡ©н•ҳм—¬ м ңмһ‘лҗң мӮ¬мІ к°•кҙҙмқҳ лҜём„ёмЎ°м§Ғмқ„ 분м„қн•ҳл Өкі н•ҳмҳҖмңјлӮҳ мһҘкё°к°„ кі„нҡҚ м •м§ҖлЎң мқён•ҙ HUNSм—җм„ң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мҲҳн–үн•ҳмҳҖлӢӨ. HUNSмқҳ мӨ‘м„ұмһҗ мҳҒмғҒ мһҘм№ҳ м„ёл¶ҖлӘ…м№ӯмқҖ Figure 2aмҷҖ к°ҷмңјл©° м „мһҗк°ҖмҶҚкё°лҘј мқҙмҡ©н•ҳм—¬ нҺ„мҠӨ мӨ‘м„ұмһҗлҘј л°ңмғқмӢңнӮӨлҠ” мӣҗлҰ¬лҠ” Figure 2bмҷҖ к°ҷлӢӨ(Figure 2). HUNSлҠ” 1.5 kW м „мһҗк°ҖмҶҚкё°м—җ мқҳн•ҙ 29.7 MeVлЎң к°ҖмҶҚлҗң м „мһҗк°Җ Pb targetм—җ л¶Җл”ӘнһҲл©ҙм„ң мҙҲлӢ№ 2 Г— 1012к°ңмқҳ мӨ‘м„ұмһҗк°Җ мғқм„ұлҗңлӢӨ. мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмҡ© м—ҙмӨ‘м„ұмһҗлҠ” Pb targetм—җм„ң л°ңмғқлҗң кі м—җл„Ҳм§Җмқҳ кі мҶҚмӨ‘м„ұмһҗлҘј нҸҙлҰ¬м—җнӢёл Ң(polyethylene)мңјлЎң к°җмҶҚмӢңмјң мӮ¬мҡ©н•ңлӢӨ(Figure 2).

HUNSм—җм„ңлҠ” л°ңмғқлҗң нҺ„мҠӨ мӨ‘м„ұмһҗлҘј мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мң„н•ҙ Gas electron multiplier (GEM) мӨ‘м„ұмһҗ мҳҒмғҒ кІҖм¶ңкё°лҘј мӮ¬мҡ©н•ҳмҳҖлӢӨ. GEM мӨ‘м„ұмһҗ мҳҒмғҒ кІҖм¶ңкё°лҠ” 128(к°ҖлЎң) Г— 128(м„ёлЎң)к°ңмқҳ н”Ҫм…Җл“ӨлЎң мқҙлЈЁм–ҙм ё мһҲмңјл©° н•ң н”Ҫм…Җмқҳ нҒ¬кё°лҠ” 800 Ојm мқҙлӢӨ. кІҖм¶ң к°ҖлҠҘн•ң мҳҒм—ӯмқҖ 10.24 cm Г— 10.24 cmмқҙлӢӨ. GEM мӨ‘м„ұмһҗ мҳҒмғҒ кІҖм¶ңкё°лҠ” к°Ғ н”Ҫм…Җлі„лЎң мӨ‘м„ұмһҗк°Җ л“Өм–ҙмҳӨлҠ” к°ңмҲҳмҷҖ лҸ„м°© мӢңк°„мқ„ мёЎм •н• мҲҳ мһҲлӢӨ. к°Ғ н”Ҫм…Җлі„лЎң мӨ‘м„ұмһҗк°Җ кІҖм¶ңкё°м—җ л“Өм–ҙмҳӨлҠ” лҸ„м°© мӢңк°„мқ„ мёЎм •н•ҳм—¬ мӨ‘м„ұмһҗмқҳ мҶҚлҸ„ лҳҗлҠ” нҢҢмһҘлі„лЎң мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјмқ„ мёЎм •н• мҲҳ мһҲлӢӨ.

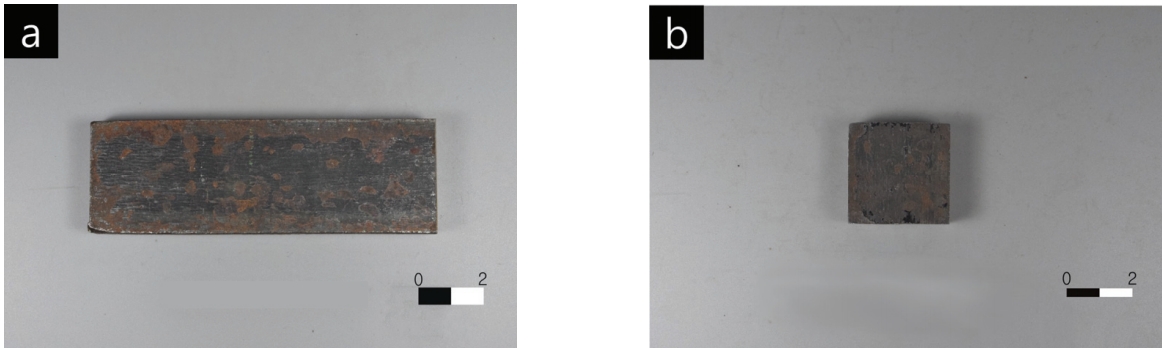

м—°кө¬ лҢҖмғҒмқҖ Figure 1мқҳ м „нҶө м ңмІ лІ•мңјлЎң мғқмӮ°лҗң мӮ¬мІ к°•кҙҙмқҙл©°, 3м Ҳм—җм„ң м„ӨлӘ…н•ң л°©лІ•мңјлЎң мғқмӮ°лҗң мӮ¬мІ к°•кҙҙмқҳ кёёмқҙлҠ” Figure 3aм—җм„ң ліј мҲҳ мһҲл“Ҝмқҙ м•Ҫ 10 cmмқҙлӢӨ(Figure 3). мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мң„н•ҙ Water-jetмқ„ мқҙмҡ©н•ҳм—¬ мӮ¬мІ к°•кҙҙлҘј Figure 3bмІҳлҹј 9 cm2мқҳ м •мӮ¬к°Ғнҳ• лӘЁм–‘(3 cm Г— 3 cm)мңјлЎң м ҲлӢЁн•ҳм—¬ 1к°ңмқҳ мӢңлЈҢ(SI-B)лҘј м ңмһ‘н•ҳмҳҖлӢӨ. м •мӮ¬к°Ғнҳ• лӘЁм–‘мңјлЎң м ҲлӢЁн•ң мқҙмң лҠ” мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қм—җ мӮ¬мҡ©лҗң мӣҗмһҗлЎңк°Җ к°ҖмҶҚкё° кё°л°ҳ мҶҢнҳ• мӨ‘м„ұмһҗ мқҙмҡ©мӢңм„Өмқҙкё° л•Ңл¬ёмқҙлӢӨ(Table 1, Figures 1 and 3).

л§Ҳм§Җл§үмңјлЎң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қ кІ°кіјмҷҖ 비көҗн•ҳкё° мң„н•ҙ лҸҷмқј мӮ¬мІ к°•кҙҙм—җм„ң кёҲмҶҚнҳ„лҜёкІҪкіј SEM 분м„қмҡ© мӢңлЈҢ 1к°ң(SI-A)лҘј м ңмһ‘н•ҳмҳҖлӢӨ(Table 1).

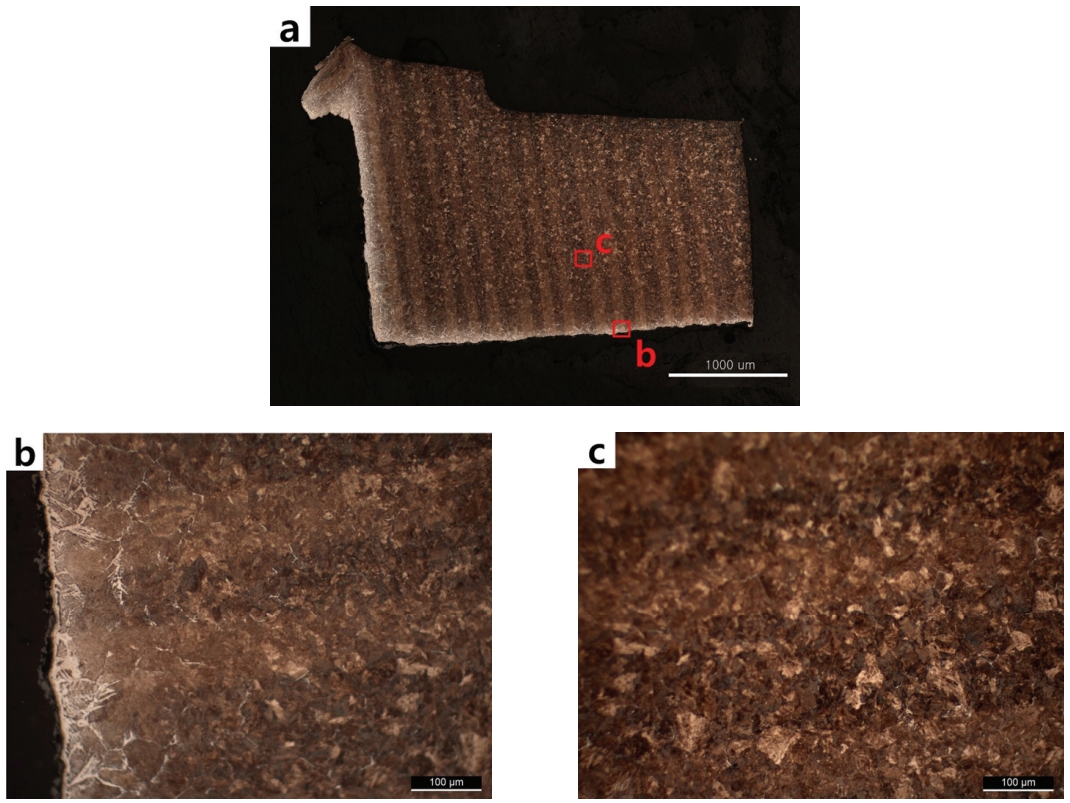

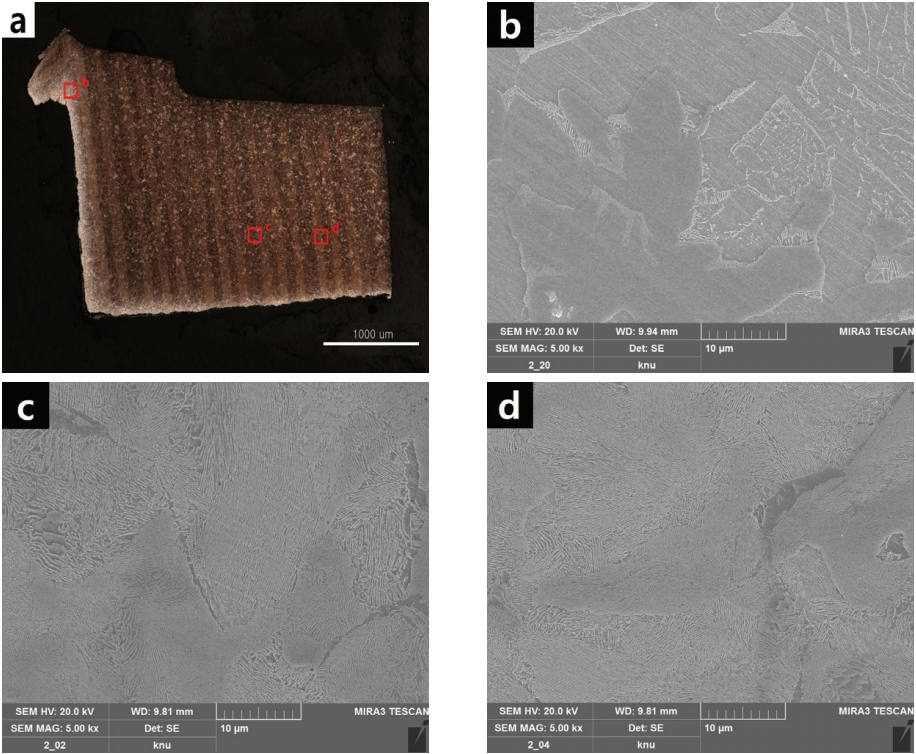

м „нҶө м ңмІ лІ•мңјлЎң мғқмӮ°лҗң мӮ¬мІ к°•кҙҙмқҳ лҜём„ёмЎ°м§Ғмқ„ кёҲмҶҚнҳ„лҜёкІҪ(DM-2500M, Leica, DEU)кіј мЈјмӮ¬м „мһҗнҳ„лҜёкІҪ(MIRA3, TESCAN, CZE) 분м„қлІ•мңјлЎң кҙҖм°°н•ҳмҳҖлӢӨ. мқҙлҘј мң„н•ҙ мӮ¬мІ к°•кҙҙм—җм„ң мӢңлЈҢ(SI-A)лҘј мӨҖ비н•ҳкі , Epoxy resinкіј Epoxy hardener(25 g : 3 g)мқ„ мқҙмҡ©н•ҳм—¬ м „мІҳлҰ¬лҘј н•ҳмҳҖлӢӨ. мӢңлЈҢ мң„м№ҳлі„лЎң кІҪн–Ҙм„ұмқ„ нҷ•мқён•ҳкё° мң„н•ҙ Figure 4aмҷҖ 5aмҷҖ к°ҷмқҙ лҢҖн‘ңм§Җм җмқ„ м„ нғқн•ҳкі лҜём„ёмЎ°м§Ғмқ„ кҙҖм°°н•ҳмҳҖлӢӨ. лҜём„ёмЎ°м§Ғ кҙҖм°°м—җ мӮ¬мҡ©лҗң 분м„қкё°кё°лҠ” кёҲмҶҚнҳ„лҜёкІҪ, мЈјмӮ¬м „мһҗнҳ„лҜёкІҪмқ„ мқҙмҡ©н•ҳмҳҖлӢӨ. л§ҲмҡҙнҢ…мқҙ лҗң мӢңлЈҢлҘј лЁјм Җ м—җм№ӯн•ҳм—¬ л¶ҖмӢқмӢңнӮЁ лӢӨмқҢ кёҲмҶҚнҳ„лҜёкІҪмқ„ мқҙмҡ©н•ҳм—¬ лҜём„ёмЎ°м§Ғмқ„ кҙҖм°°н•ҳмҳҖлӢӨ. мқҙ нӣ„ мӢңлЈҢмқҳ м „лҸ„лҸ„лҘј лҶ’мқҙкё° мң„н•ҙ л°ұкёҲ(Pt)мңјлЎң мҪ”нҢ…мқ„ н•ң нӣ„ кёҲмҶҚнҳ„лҜёкІҪліҙлӢӨ лҶ’мқҖ л°°мңЁмқҳ мЈјмӮ¬м „мһҗнҳ„лҜёкІҪмқ„ мқҙмҡ©н•ҳм—¬ м„ёл¶Җм Ғмқё лҜём„ёмЎ°м§Ғмқ„ кҙҖм°°н•ҳмҳҖлӢӨ.

мӨ‘м„ұмһҗ мҳҒмғҒмқҖ 비нҢҢкҙҙкІҖмӮ¬м—җ мқјл°ҳм ҒмңјлЎң нҷңмҡ©лҗҳлҠ” X-м„ мҳҒмғҒкіј 비мҠ·н•ң мӣҗлҰ¬лЎң, л¬јм§Ҳл§ҲлӢӨ м„ңлЎң лӢӨлҘё мӨ‘м„ұмһҗ нҲ¬кіјмңЁмқ„ мқҙмҡ©н•ҳлҠ” кІғмқҙлӢӨ. к·ё мӨ‘м—җм„ңлҸ„ к°ҷмқҖ л¬јм§ҲмқҙлқјлҸ„ мӨ‘м„ұмһҗ нҲ¬кіјмңЁмқҖ мӨ‘м„ұмһҗмқҳ нҢҢмһҘлі„лЎң лӢӨлҘҙл©°, мӮ¬мІ к°•кҙҙмқҳ кІҪмҡ° Bragg мӮ°лһҖм—җ мқҳн•ҙ нҠ№м • нҢҢмһҘм—җм„ң мӨ‘м„ұмһҗ нҲ¬кіјкі„мҲҳк°Җ кёүкІ©нһҲ ліҖн•ҳлҠ” Bragg edge нҳ„мғҒмқ„ кҙҖм°°н• мҲҳ мһҲлӢӨ. мӮ¬мІ к°•кҙҙмқҳ мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹј 분м„қмқ„ нҶөн•ҙ мӢңлЈҢ лӮҙл¶ҖмқҳмғҒ 분нҸ¬мҷҖ кІ°м • нҒ¬кё° л“ұмқҳ мҳҒмғҒнҷ” л°Ҹ м •лҹүнҷ”к°Җ к°ҖлҠҘн•ҳлӢӨ. мӮ¬мІ к°•кҙҙмқҳ мғҒ분нҸ¬лҠ” Single Bragg edge profile 분м„қмқ„ нҶөн•ҙ мёЎм •н•ҳмҳҖмңјл©° кІ°м • нҒ¬кё°лҠ” Full pattern rietveld fitting 분м„қмқ„ нҶөн•ҙ мёЎм •н•ҳмҳҖлӢӨ(Sato et al, 2011; 2015). лӘЁл“ 분м„қмқҖ SI-Bмқҳ м „мІҙм Ғмқё л¶Җ분м—җм„ң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқҙ мқҙлЈЁм–ҙмЎҢлӢӨ.

SI-Aмқҳ лҜём„ёмЎ°м§ҒмқҖ кёҲмҶҚнҳ„лҜёкІҪкіј мЈјмӮ¬м „мһҗнҳ„лҜёкІҪ кІ°кіјм—җм„ң нҷ•мқён• мҲҳ мһҲлӢӨ(Figure 4, 5). SI-AлҠ” нғ„мҶҢн•Ёлҹүмқҳ м°ЁмқҙлЎң мқён•ҳм—¬ лӢӨмҲҳмқҳ мёөмқҙ кҙҖм°°лҗҳм—ҲлӢӨ. Figure 4лҘј нҶөн•ҙ к°Җм—ҙлҗң мӮ¬мІ к°•кҙҙк°Җ м„ңм„ңнһҲ лғүк°Ғлҗҳл©ҙм„ң мІҙмӢ¬мһ…л°©кІ©мһҗ(body-centered cubic, BCC) кө¬мЎ°мқё нҺҳлқјмқҙнҠё(ferrite)мҷҖ мёөмғҒкө¬мЎ°(lamella structure)мқҳ нҺ„лқјмқҙнҠё(pearlite)к°Җ кҙҖм°°лҗҳм—ҲлӢӨ. лҳҗн•ң Figure 4bлҘј нҶөн•ҙ мқјл¶Җ SI-Aмқҳ к°ҖмһҘмһҗлҰ¬м—җм„ң нҺ„лқјмқҙнҠё(pearlite) лӮҙл¶ҖлЎң м„ұмһҘн•ң 비л“ңл§ҢмҠӨн…ҢнҠј нҺҳлқјмқҙнҠё(Widmanst У“tten ferrite) мЎ°м§Ғмқҙ кҙҖм°°лҗҳм—ҲлӢӨ. лҳҗн•ң к°ҖмһҘмһҗлҰ¬к°Җ нғҲнғ„мқҙ мқҙлЈЁм–ҙм ё лӮҙл¶Җмқҳ лҜём„ёмЎ°м§ҒліҙлӢӨ л°қмқҖ мЎ°м§Ғмқҙ мһҲлӢӨлҠ” кІғмқ„ кҙҖм°°н•ҳмҳҖлӢӨ. л§Ҳм§Җл§үмңјлЎң SI-Aмқҳ grain sizeк°Җ лӢЁмЎ°лЎң мқён•ҳм—¬ лҜём„ён•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖмңјлӮҳ, м •нҷ•н•ң мҲҳм№ҳлЎң кі„мӮ°н•ҳм—¬ к°қкҙҖнҷ”лҘј н• мҲҳлҠ” м—Ҷм—ҲлӢӨ(Figure 4).

кёҲмҶҚнҳ„лҜёкІҪмқ„ нҶөн•ҙ кҙҖм°°н•ң SI-AлҘј лӢӨмӢң SEMмқ„ нҶөн•ҳм—¬ кі л°°мңЁлЎң м„ёл¶Җм Ғмқё лҜём„ёмЎ°м§Ғмқ„ кҙҖм°°н•ҳмҳҖлӢӨ. мЈјмӮ¬м „мһҗнҳ„лҜёкІҪ(SEM)мқ„ нҶөн•ҙ кҙҖм°°н•ң кІ°кіј м „мІҙм ҒмңјлЎң нҺҳлқјмқҙнҠё(ferrite)мҷҖ мёөмғҒмқҳ нҺ„лқјмқҙнҠё(pearlite)мқҳ нҳ•нғңлЎң кҙҖм°°лҗҳм—ҲлӢӨ. мқјл¶Җ Figure 5bмҷҖ к°ҷмқҖ к°ҖмһҘмһҗлҰ¬ л¶Җ분м—җм„ңлҠ” мЎ°лҢҖн•ң нҺҳлқјмқҙнҠё(ferrite)к°Җ кҙҖм°°лҗҳм—ҲлӢӨ(Figure 5).

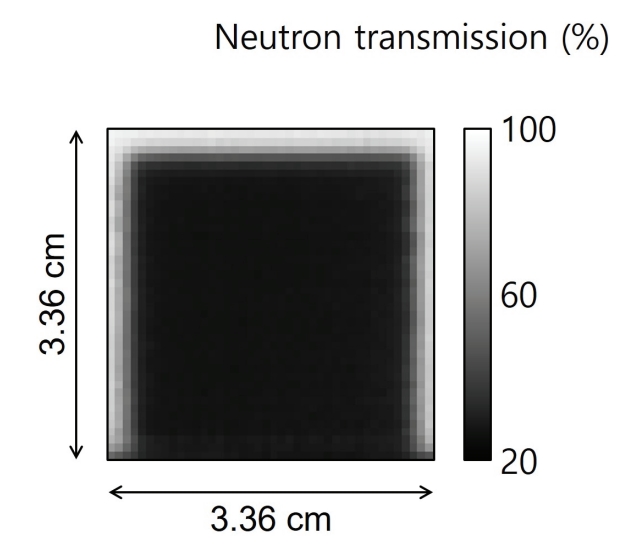

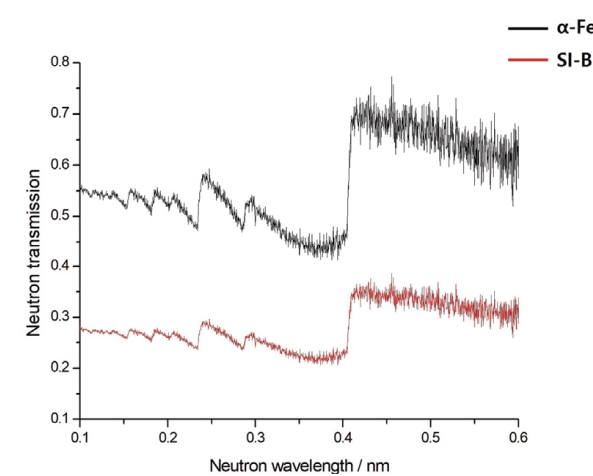

SI-Bмқҳ мӨ‘м„ұмһҗ нҢҢмһҘлі„(О» = 1вҲј8 в„«) мҳҒмғҒмқ„ нҡҚл“қн•ҳмҳҖмңјл©° лӘЁл“ мӨ‘м„ұмһҗ нҢҢмһҘлі„ мҳҒмғҒмқҙ н•©міҗ진 мқјл°ҳм Ғмқё мӨ‘м„ұмһҗ нҲ¬кіј мҳҒмғҒмқ„ нҷ•мқён•ң кІ°кіј к°ҷмқҖ л¬јм§Ҳм—җ к°ҷмқҖ л‘җк»ҳмқҙкё° л•Ңл¬ём—җ к·ёлҰј Figure 6кіј к°ҷмқҙ лҸҷмқјн•ң мӨ‘м„ұмһҗ нҲ¬кіјлҸ„к°Җ лӮҳмҳӨкі мһҲлӢӨ(Figure 6).

мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјмқҖ мӨ‘м„ұмһҗ мҳҒмғҒмқҳ нҠ№м • н”Ҫм…Җ лҳҗлҠ” мҳҒм—ӯмқҳ к°’мқ„ нҢҢмһҘлі„лЎң лӮҳнғҖлӮҙл©° м•„лһҳмқҳ Figure 7кіј к°ҷмқҙ кө¬н• мҲҳ мһҲлӢӨ. м ңмһ‘лҗң мӮ¬мІ к°•кҙҙмқҳ мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјмқ„ BCC кө¬мЎ°лҘј к°Җм§ҖлҠ” Figure 7мқҳ Оұ-Feмқҳ мҠӨнҺҷнҠёлҹјкіј 비көҗн–Ҳмқ„ л•Ң лҸҷмқјн•ң x축(neutron wavelength)м—җм„ң 비мҠ·н•ң кІҪн–Ҙм„ұмқ„ ліҙмқҙкі мһҲлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ(Figure 7). лӢӨл§Ң y축(neutron transmission)м—җм„ң лҶ’лӮ®мқҙ м°Ёмқҙк°Җ мһҲлҠ”лҚ° мқҙлҠ” н‘ңмӨҖмӢңлЈҢмқҳ л‘җк»ҳк°Җ SI-BліҙлӢӨ м–Үм•„ SI-BліҙлӢӨ мӨ‘м„ұмһҗк°Җ лҚ” л§Һмқҙ нҲ¬кіјлҗҳм—Ҳкё° л•Ңл¬ёмқҙлӢӨ. мў…н•©н•ҳл©ҙ SI-BлҠ” BCC кө¬мЎ°мқҳ нҺҳлқјмқҙнҠё(ferrite)лЎң нҷ•мқён•ҳмҳҖлӢӨ.

SI-BлҠ” лҸҷмқјн•ң л‘җк»ҳмқҳ мҲңмҲҳн•ң мІ мқҙкё° л•Ңл¬ём—җ мӨ‘м„ұмһҗ нҢҢмһҘлі„ мҳҒмғҒмқ„ нҶөн•ҙ лҸҷмқјн•Ёмқ„ нҷ•мқён•ҳмҳҖмңјл©°, лҸҷмӢңм—җ лӮҙл¶Җмқҳ кіөк·№мқҙлӮҳ кІ°н•Ёмқҙ м—ҶмқҢмқ„ нҷ•мқён•ҳмҳҖлӢӨ. лҳҗн•ң мғқмӮ°лҗң к°•кҙҙм—җм„ң BCC кө¬мЎ°мқҳ Оұ-Feмқё нҺҳлқјмқҙнҠё(ferrite)мҷҖ нҺ„лқјмқҙнҠё(pearlite)лҘј нҷ•мқён•ҳмҳҖлӢӨ.

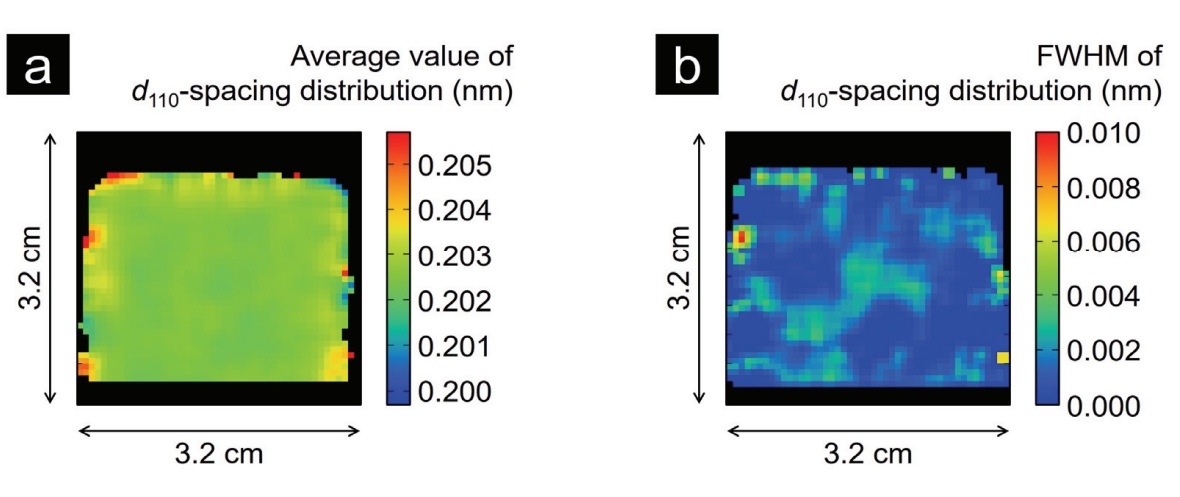

мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјмқҖ мӨ‘м„ұмһҗ нҲ¬кіј мҳҒмғҒмқҳ лӘЁл“ н”Ҫм…Җмқҳ к°ңлі„лЎң нҡҚл“қмқҙ к°ҖлҠҘн•ҳлӢӨ. м ңмһ‘лҗң мӮ¬мІ к°•кҙҙмқҳ кІ°м •н•ҷм Ғ мғҒ(phase) 분м„қмқҖ мӨ‘м„ұмһҗ нҢҢмһҘ 4 в„« мЈјмң„м—җм„ң л°ңмғқн•ҳлҠ” Single Bragg edge profile 분м„қмқ„ нҶөн•ҙ к°ҖлҠҘн•ҳлӢӨ. BCC кө¬мЎ°м—җм„ң лӮҳнғҖлӮҳлҠ” Bragg edgeмқҳ мң„м№ҳлҠ” Bragg мЎ°кұҙм—җ мқҳн•ҙ О» = 2d110м—җм„ң лӮҳнғҖлӮҳл©° мІҙмӢ¬м •л°©кІ©мһҗ(body-centered tetragonal, BCT) кө¬мЎ° лҳҗлҠ” л©ҙмӢ¬мһ„л°©кІ©мһҗ(face-centered cubic, FCC) кө¬мЎ°лЎң ліҖнғңк°Җ мқјм–ҙлӮҳл©ҙ мқҙлҸҷн•ҳкІҢ лҗңлӢӨ. Bragg edge мң„м№ҳ нҸүк· к°’(d110)мқ„ к°Ғ н”Ҫм…Җлі„лЎң мёЎм •н•ҳм—¬ м•„лһҳ Figure 8aмҷҖ к°ҷмқҙ мҳҒмғҒнҷ” н•ҳмҳҖлӢӨ. BCC кө¬мЎ°мқҳ Bragg edge мң„м№ҳ нҸүк· к°’(d110)мқҖ ліҙнҶө 2.02 в„«м—җм„ң 2.03 в„« мӮ¬мқҙлЎң кҙҖм°°лҗңлӢӨ. мқҙлҘј нҶ лҢҖлЎң м ңмһ‘лҗң мӮ¬мІ к°•кҙҙлҘј мӮҙнҺҙліё кІ°кіј, м „л°ҳм ҒмңјлЎң 2.02 в„«м—җм„ң 2.03 в„« мӮ¬мқҙлЎң кҙҖм°°лҗҳл©° SI-Bмқҳ к°ҖмһҘмһҗлҰ¬ л¶Җ분м—җм„ң мқјл¶Җ 2.05 в„« нҳ№мқҖ 2.00 в„« к°ҷмқҙ нҷ•мқёлҗҳм—ҲлӢӨ(Figure 8).

мӮ¬мІ к°•кҙҙм—җм„ң мғҒ ліҖнғңк°Җ мқјм–ҙлӮҳл©ҙ мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјм—җм„ң Bragg edgeмқҳ мң„м№ҳ мқҙлҸҷкіј лҚ”л¶Ҳм–ҙ Bragg edgeмқҳ нҸӯмқҙ л„“м–ҙм§ҖкІҢ лҗңлӢӨ. Bragg edge л°ҳк°ҖнҸӯ(Full width half maximum, FWHM)мқ„ к°Ғ н”Ҫм…Җлі„лЎң мёЎм •н•ҳм—¬ м•„лһҳ Figure 8bмҷҖ к°ҷмқҙ мҳҒмғҒнҷ” н•ҳмҳҖлӢӨ. SI-Bмқҳ Bragg edge л°ҳк°ҖнҸӯмқҖ 0.00 в„«вҲј0.02 в„«мӮ¬мқҙлЎң BCC кө¬мЎ°мқҳ Bragg edge л°ҳк°ҖнҸӯкіј мқјм№ҳн•ҳлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ(Figure 8).

л”°лқјм„ң кі лҢҖ м „нҶөм ңмІ лІ•мқ„ нҶөн•ҙ мғқмӮ°лҗң SI-BлҠ” мқјл¶Җ к°ҖмһҘмһҗлҰ¬лҘј м ңмҷён•ҳкі м „л°ҳм ҒмңјлЎңлҠ” BCC кө¬мЎ°мқҳ Bragg edge мң„м№ҳ нҸүк· к°’(d110)кіј мң мӮ¬н•ҳм—¬ BCC кө¬мЎ°мһ„мқ„ нҷ•мқён•ҳмҳҖлӢӨ. лҳҗн•ң Bragg edge л°ҳк°ҖнҸӯмқ„ нҷ•мқён•ҳм—¬лҸ„ BCC кө¬мЎ°к°Җ к°Җм§ҖлҠ” л°ҳк°ҖнҸӯмқё 0.00 в„«м—җм„ң 0.02 в„«мӮ¬мқҙлЎң лҸҷмқјн•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ.

SI-Bмқҳ мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјм—җм„ң лӘЁл“ мҳҒм—ӯ(О» = 1вҲј8 в„«)мқ„ мқҙмҡ©н•ҳлҠ” Full pattern rietveld fitting 분м„қмқ„ нҶөн•ҙ н•ң н”Ҫм…Җ нҒ¬кё°мқё 800 Ојm2 мҳҒм—ӯм—җм„ң SI-Bмқҳ нҸүк· grain sizeлҘј нҡҚл“қн•ҳмҳҖмңјл©° 1282к°ңмқҳ н”Ҫм…Җл“ӨлЎң м•„лһҳ Figure 9мҷҖ к°ҷмқҙ мҳҒмғҒнҷ” н•ҳмҳҖлӢӨ. м ңмһ‘лҗң SI-Bмқҳ нҸүк· grain sizeлҠ” лҢҖлһөм ҒмңјлЎң 3 Ојmм •лҸ„лЎң нҷ•мқёлҗҳм—ҲлӢӨ. лҳҗн•ң SI-Bмқҳ к°ҖмһҘмһҗлҰ¬мқҳ мқјл¶Җм—җм„ң нҸүк· grain sizeліҙлӢӨ мғҒлҢҖм ҒмңјлЎң нҒ¬кұ°лӮҳ мһ‘мқҖ кІғлҸ„ кҙҖм°°лҗҳм—ҲмңјлӮҳ, н•ҙлӢ№ SI-Bмқҳ м „л°ҳм Ғмқё grain sizeлҠ” мғҒлӢ№нһҲ лҜём„ён•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ(Figure 9).

н•ҙлӢ№ SI-Bмқҳ grain sizeк°Җ лҢҖлһө 3 Ојmм •лҸ„мқҳ лҜём„ён•ң нҒ¬кё°лқјлҠ” кІғмқ„ Full pattern rietveld fitting 분м„қмңјлЎң нҷ•мқён•ҳмҳҖмңјл©°, мқҙлҠ” м ңмһ‘кіөм •м—җм„ң мӢңн–үлҗҳлҠ” л§қм№ҳлЎң мқён•ң лӢЁмЎ°мһ‘м—… л•Ңл¬ёмңјлЎң нҢҗлӢЁн•ҳмҳҖлӢӨ.

ліё м—°кө¬мқҳ лӘ©м ҒмқҖ кі лҢҖ м „нҶөм ңмІ лІ•мқ„ нҶөн•ҙ мғқмӮ°лҗң мӮ¬мІ к°•кҙҙмқҳ кёҲмҶҚн•ҷм Ғ нҠ№м„ұмқ„ м•Ңм•„ліҙкі мһҗ нҢҢкҙҙ분м„қ л°©лІ•кіј 비нҢҢкҙҙ분м„қ л°©лІ•мқ„ мӮ¬мҡ©н•ҳм—¬ 분м„қн•ҳм—¬ 비көҗн•ҳмҳҖлӢӨ. мқҙлҘј нҶөн•ҙ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқҙ мӢңлЈҢмқҳ 비нҢҢкҙҙ분м„қм—җ нҷңмҡ©н• мҲҳ мһҲмқҢмқ„ нҷ•мқён•Ёкіј лҸҷмӢңм—җ л¬ёнҷ”мһ¬м—җлҸ„ м Ғмҡ© к°ҖлҠҘн•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳкі мһҗ н•ҳлҠ” кІғмқҙлӢӨ.

нҢҢкҙҙ분м„қлІ•мңјлЎңлҠ” нҳ„лҜёкІҪкҙҖм°°мқ„ мқҙмҡ©н•ҳмҳҖкі , 비нҢҢкҙҙ분м„қлІ•мңјлЎң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мқҙмҡ©н•ҳмҳҖлӢӨ. лЁјм Җ нҢҢкҙҙ분м„қлІ•мқё кёҲмҶҚнҳ„лҜёкІҪкіј SEMмқ„ мқҙмҡ©н•ҙ кҙҖм°°н•ң кІ°кіј SI-Aм—җм„ң лҜём„ён•ң grain sizeмқҳ нҺҳлқјмқҙнҠё(ferrite)мҷҖ мёөмғҒкө¬мЎ°(lamella structure)мқҳ нҺ„лқјмқҙнҠё(pearlite)к°Җ м „мІҙм ҒмңјлЎң нҷ•мқёлҗҳм—ҲлӢӨ. лҳҗн•ң мӢңлЈҢмқҳ к°ҖмһҘмһҗлҰ¬м—җм„ң мқјл¶Җ нҺ„лқјмқҙнҠё(pearlite) лӮҙл¶ҖлЎң м„ұмһҘн•ң кіјм—ҙлғүк°ҒмЎ°м§Ғмқё 비л“ңл§ҢмҠӨн…ҢнҠј нҺҳлқјмқҙнҠё(WidmanstГӨtten ferrite)к°Җ кҙҖм°°лҗҳм—ҲлӢӨ. к·ёлҰ¬кі мқјл¶Җ к°ҖмһҘмһҗлҰ¬мқҳ кёҲмҶҚмЎ°м§Ғмқҙ лӮҙл¶ҖмЎ°м§ҒліҙлӢӨ л°қкІҢ кҙҖм°°лҗҳм—ҲлҠ”лҚ°, мқҙлҠ” л°қмқҖ л¶Җ분м—җм„ң нғҲнғ„мқҙ мқҙлЈЁм–ҙмЎҢкё° л•Ңл¬ёмңјлЎң ліҙмқёлӢӨ. лҜём„ён•ң кёҲмҶҚмЎ°м§Ғмқҙ кҙҖм°°лҗң мқҙмң лҠ” л§қм№ҳлҘј мқҙмҡ©н•ң л§ҺмқҖ лӢЁмЎ°к°Җ мқҙлЈЁм–ҙмЎҢкё° л•Ңл¬ёмқҙм—ҲлӢӨ. н•ҳм§Җл§Ң мңЎм•ҲмЎ°мӮ¬лҘј нҶөн•ҙ лҜём„ён•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖмқ„ лҝҗ мқҙлҘј мҲҳм№ҳлЎң к°қкҙҖнҷ”н• мҲҳлҠ” м—Ҷм—ҲлӢӨ.

нҢҢкҙҙ분м„қлІ•мқё кёҲмҶҚнҳ„лҜёкІҪкіј SEM 분м„қмқ„ нҶөн•ҙ нҷ•мқёлҗң кІ°кіјлҘј 비нҢҢкҙҙ분м„қ кІ°кіјмҷҖ 비көҗн•ҳкё° мң„н•ҙ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мқјліё нӣ—м№ҙмқҙлҸ„ лҢҖн•ҷмқҳ мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қ мӢңм„Өмқё HUNSлҘј мқҙмҡ©н•ҳм—¬ 분м„қн•ҳмҳҖлӢӨ. мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қ кІ°кіј SI-Bмқҳ мӨ‘м„ұмһҗ нҲ¬кіј мҠӨнҺҷнҠёлҹјмқҖ BCC кө¬мЎ°мқҳ н‘ңмӨҖ Оұ-Feмқё нҺҳлқјмқҙнҠё(ferrite)мқҳ мҠӨнҺҷнҠёлҹјкіј 비мҠ·н•ң м–‘мғҒмқ„ ліҙмҳҖлӢӨ. лҳҗн•ң SI-Bмқҳ кІ°м •н•ҷм Ғ мғҒ(phase) 분м„қмқ„ мң„н•ҙ мӨ‘м„ұмһҗ нҢҢмһҘ 4 в„« мЈјмң„м—җм„ң л°ңмғқн•ҳлҠ” Single Bragg edge profile 분м„қмқ„ мқҙмҡ©н•ҳмҳҖлӢӨ. мқҙлҘј нҶөн•ҙ мқјл¶Җ к°ҖмһҘмһҗлҰ¬лҘј м ңмҷён•ҳкі м „л°ҳм ҒмңјлЎңлҠ” BCC кө¬мЎ°мқҳ Bragg edge мң„м№ҳ нҸүк· к°’(d110)кіј мң мӮ¬н•ҳм—¬ BCC кө¬мЎ°мһ„мқ„ нҷ•мқён•ҳмҳҖлӢӨ. лҳҗн•ң Bragg edge л°ҳк°ҖнҸӯ м—ӯмӢң BCC кө¬мЎ°к°Җ к°Җм§ҖлҠ” л°ҳк°ҖнҸӯмқё 0.00 в„«м—җм„ң 0.02 в„«мӮ¬мқҙлЎң лҸҷмқјн•ҳлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ. л§Ҳм§Җл§үмңјлЎң Full pattern rietveld fitting 분м„қмңјлЎң grain sizeлҘј нҷ•мқён•ң кІ°кіј лҢҖлһөм ҒмңјлЎң 3 Ојm м •лҸ„лЎң кҙҖм°°лҗҳм—ҲлӢӨ.

к°ҷмқҖ мӢңлЈҢм—җ лҢҖн•ҙ нҢҢкҙҙ분м„қлІ•кіј 비нҢҢкҙҙ분м„қлІ•мқ„ 비көҗн•ң кІ°кіј лҸҷмқјн•ң 분м„қк°’мқ„ нҷ•мқён•ҳмҳҖлӢӨ. лҚ” лӮҳм•„к°Җ 비нҢҢкҙҙ분м„қ л°©лІ•мқё мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мқҙмҡ©н•ңлӢӨл©ҙ кёҲмҶҚмЎ°м§Ғкіј кІ°м •кө¬мЎ° нҳ№мқҖ grain sizeм—җ лҢҖн•ҳм—¬ мҲҳм№ҳнҷ”лҗң к°қкҙҖм Ғмқё м§Җн‘ң нҡҚл“қкіј лҚ”л¶Ҳм–ҙ мӢңк°Ғм ҒмңјлЎң мүҪкІҢ мӢқлі„мқҙ к°ҖлҠҘн•ң 분м„қкІ°кіјлҘј м–»мқ„ мҲҳ мһҲлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ.

мқҙлҘј нҶөн•ҙ мҷ„м „н•ң 비нҢҢкҙҙ 분м„қ л°©лІ•мқё мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқ„ мқҙмҡ©н•ңлӢӨл©ҙ л¬ёнҷ”мһ¬м—җм„ң лі„лҸ„мқҳ мӢңлЈҢлҘј нҡҚл“қн• н•„мҡ”к°Җ м—Ҷм–ҙ мӣҗнҳ•мқҳ нӣјмҶҗм—Ҷмқҙ 분м„қкІ°кіјлҘј лҸ„м¶ңн• мҲҳ мһҲлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ. мқҙлҘј нҶөн•ҙ 분м„қн•ҳкё° м–ҙл Өмҡҙ л¬ёнҷ”мһ¬м—җ лҢҖн•ң лӢӨм–‘н•ң мһ¬лЈҢкіјн•ҷм Ғ нҠ№м„ұкіј м ңмһ‘кё°лІ•м—җ лҢҖн•ң н•ҙлІ•мқ„ м ңмӢңн• мҲҳ мһҲмқ„ кІғмңјлЎң мғқк°ҒлҗңлӢӨ.

н•ҳм§Җл§Ң мӨ‘м„ұмһҗ мҳҒмғҒ 분м„қмқҖ л¬ёнҷ”мһ¬м—җ мӨ‘м„ұмһҗлҘј мЎ°мӮ¬н•ҳлҠ” 분м„қл°©лІ•мқҙлҜҖлЎң мӢңлЈҢмқҳ л°©мӮ¬нҷ”к°Җ лҗ мҲҳ мһҲлӢӨлҠ” мқҳкө¬мӢ¬кіј мӨ‘м„ұмһҗ мЎ°мӮ¬лЎң мқён•ң мһ¬м§Ҳмқҳ м—ҙнҷ” нҳ№мқҖ мҶҗмғҒ л“ұмқҙ м•јкё°лҗ мҲҳ мһҲлӢӨлҠ” мқҳкө¬мӢ¬мқҙ мЎҙмһ¬н•ҳкі мһҲлӢӨ. лЁјм Җ мІ« лІҲм§ё мқҳкө¬мӢ¬мқё мӢңлЈҢ л°©мӮ¬нҷ”мқҳ кІҪмҡ° мҷёкөӯмқҳ л¬ёнҷ”мһ¬ 분м„қ мӮ¬лЎҖм—җм„ң ліҙл©ҙ мӢңк°„мқҙ м§ҖлӮ мҲҳлЎқ л°©мӮ¬лҠҘмқҙ м җм°Ё л–Ём–ҙм ё мқёмІҙм—җ мң н•ҙн• л§ҢнҒј мһ”мЎҙн•ҳм§Җ м•ҠлӢӨлҠ” кІғмқ„ нҷ•мқён• мҲҳ мһҲлӢӨ. лҳҗн•ң л‘җ лІҲм§ё мқҳкө¬мӢ¬ м—ӯмӢң н•ҙмҷё л¬ёнҷ”мһ¬ 분м„қ мӮ¬лЎҖлҘј нҶөн•ҙ мһ¬м§Ҳлі„ нҳ•мғҒліҖнҷ”к°Җ м—ҶлӢӨлҠ” кІғмқ„ нҷ•мқён•ҳмҳҖлӢӨ. нҠ№нһҲ мӨ‘м„ұмһҗлҘј мқҙмҡ©н•ң нӣҲмҰқлҸ„ мқҙлЈЁм–ҙ진лӢӨлҠ” кІғлҸ„ мқҙлҘј мҰқлӘ…н• мҲҳ мһҲлӢӨ. к·ёлҹ¬лӮҳ мӨ‘м„ұмһҗ мЎ°мӮ¬лЎң мқён•ң л¬ёнҷ”мһ¬мқҳ мһ¬м§Ҳлі„ нҳ•мғҒліҖнҷ” л°Ҹ л°©мӮ¬лҠҘ мҲҳм№ҳ ліҖнҷ”м—җ лҢҖн•ң 추к°Җм Ғмқё м—°кө¬лҘј нҶөн•ҙ м •лҹүм Ғмқё лҚ°мқҙн„° нҡҚл“қ л°Ҹ м •лҰ¬к°Җ н•„мҡ”н• кІғмңјлЎң нҢҗлӢЁлҗңлӢӨ.

лҳҗн•ң мқјліё нӣ—м№ҙмқҙлҸ„ лҢҖн•ҷмқҳ HUNSлҠ” к°ҖмҶҚкё° кё°л°ҳ мҶҢнҳ• мӨ‘м„ұмһҗ мқҙмҡ©мӢңм„Өмқҙкё° л•Ңл¬ём—җ н•ҙмғҒлҸ„ л©ҙм—җм„ң 분н•ҙлҠҘмқҙ м•Ҫк°„мқҖ л–Ём–ҙ진лӢӨлҠ” кІғмқ„ нҷ•мқён• мҲҳ мһҲлӢӨ. мқҙлЎң мқён•ҙ Mapping н•ҙм„қм—җм„ң лҜём„ёмЎ°м§Ғмқ„ лҚ” 세분нҷ”н•ҳм—¬ нҷ•мқён•ҳлҠ” кІғмқҖ м–ҙл Өмӣ лӢӨ. мқҙ л¶Җ분мқҖ кІҖм¶ңкё°мқҳ н”Ҫм…ҖмҲҳ л°Ҹ нҒ¬кё°мҷҖ кҙҖл Ёмқҙ к№ҠмқҖлҚ° мқҙлҠ” н”Ҫм…ҖмҲҳлҘј м§ҖкёҲліҙлӢӨ лҚ”мҡұ лҠҳл Ө 분м„қн• н•„мҡ”к°Җ мһҲлӢӨ. л”°лқјм„ң н”Ҫм…ҖмҲҳлҘј к°ңлҹүн•ҳкұ°лӮҳ н”Ҫм…Җмқҳ нҒ¬кё°лҘј м§ҖкёҲліҙлӢӨ мһ‘кІҢ л§Ңл“ңлҠ” л°©лІ•мқ„ 추к°Җм ҒмңјлЎң м—°кө¬н•ҙм•ј н• кІғмңјлЎң ліҙмқёлӢӨ. н•ҳм§Җл§Ң HUNSмқҳ кІҪмҡ° к°ҖмҶҚкё° кё°л°ҳ мҶҢнҳ• мӨ‘м„ұмһҗ мқҙмҡ©мӢңм„Өмқҙкё° л•Ңл¬ём—җ ліҙлӢӨ лҢҖнҳ•мӢңм„Өмқҙл©° м—°кө¬мҡ© мӣҗмһҗлЎңмқё лҢҖн•ңлҜјкөӯмқҳ вҖҳн•ҳлӮҳлЎң(HANARO)вҖҷлҘј нҶөн•ң 분м„қмқ„ нҶөн•ҙ лҚ” мўӢмқҖ 분н•ҙлҠҘмқ„ нҷ•мқён• мҲҳ мһҲмқ„ кІғмңјлЎң ліҙмқёлӢӨ.

мӮ¬ мӮ¬

мқҙ л…јл¬ёмқҖ 2019л…„лҸ„ м •л¶Җ(м •ліҙнҶөмӢ кіјн•ҷкё°мҲ л¶Җ)мқҳ мһ¬мӣҗмңјлЎң н•ңкө¬м—°кө¬мһ¬лӢЁ м „нҶөл¬ёнҷ”мңөн•©м—°кө¬мӮ¬м—…мқҳ м§Җмӣҗмқ„ л°ӣм•„ мҲҳн–үлҗң м—°кө¬мһ„(No. NRF-2016M3C1B5906955)

FigureВ 1.

Refining and forge welding process. (a) The bloom after smelting, (b) Heating smithery hearth till 1,200в„ғ, (c) Folding the bar in half, (d) Forge welding the bar, (e) Applying charcoal powder over the bar, (f) Coating the bar with loess, (g) Reheating forge welded bar, (h) Finished bar at every stage of the refining and forge welding(Oh et al., 2018).

FigureВ 2.

Images of Hokkaido University Neutron Source (HUNS). (a) The photo of the HUNS, (b) The principal of generating pulse neutrons(Sato et al, 2018).

FigureВ 3.

Images of Sand iron. (a) Sand iron bar reproduced by traditional-making method, (b) Sand iron cut by water-jet for neutron imaging analysis.

FigureВ 4.

Metallurgical microscope photos of SI-A. (a) A metallurgical microscope scale(Г— 5), (b, c) A metallurgical microscope scale(Г— 20).

FigureВ 5.

SEM photos of SI-A. (a) Picture of metallurgical microscope, (b, c, d) SEM images for position of Figure 5a.

REFERENCES

Cho, H.K., 2015, Manufacturing technology of iron swords in the Midwestern Korea from 2nd to 6th century AD, Ph.D. dissertation, Kongju University, Gongju. (in Korean with English abstract)

Cho, S.M., Cho, H.K., Gwon, I.C. and Cho, N.C., 2018a, Material characteristic of slags and iron bloom produced by smelting process using sand iron. Journal of Conservation Science, 34(1), 39вҖ“50. (in Korean with English abstract)

Cho, S.M., Cho, N.C. and Han, J.U., 2018b, A comparative study on the metallurgical characteristics of the iron knife using traditional iron-making method. Journal of Conservation Science, 34(5), 433вҖ“441. (in Korean with English abstract)

Ministry of Science, Technology, 2004, Research on archeologic relics using neutron radiography, (in Korean with English abstract)

Nagashima, S., Shiota, Y., Sato, H., Kamiyama, T., Ohnuma, M. and Kiyanagi, Y., 2014, Imaging of crystalline structural information of Japanese swords by pulsed neutron transmission spectroscopy. Physics Procedia, 60, 327вҖ“331.

Oh, M.J., Cho, H.K., Cho, N.C. and Han, K.U., 2018, Material characteristics of forge welded bar and byвҖҗ product through reproduction experiment to the refining and forge welding process. Journal of Conservation Science, 34(2), 87вҖ“96. (in Korean with English abstract)

Sato, H., Kamiyama, T. and Kiyanagi, Y., 2011, A rietveld-type analysis code for pulsed neutron Bragg-edge transmission imaging and quantitative evaluation of texture and microstructure of a welded Оұ-iron plate. Materials Transactions, 52(6), 1294вҖ“1302.

Sato, H., Sato, T., Shiota, Y., Kamiyama, T., Tremsin, A.S., Ohnuma, M. and Kiyanagi, Y., 2015, Relation between Vickers hardness and Bragg-edge broadening in quenched steel rods observed by pulsed neutron transmission imaging. Materials Transactions, 56(8), 1147вҖ“1152.

Sato, H., Sasaki, T., Moriya, T., Ishikawa, H., Kamiyama, T. and Furusaka, M., 2018, High wavelength-resolution Bragg-edge/dip transmission imaging instrument with a supermirror guide-tube coupled to a decoupled thermalneutron moderator at Hokkaido University Neutron Source. Physica B: Condensed Matter, 551(15), 452вҖ“459.

- TOOLS

-

METRICS

-

- 1 Crossref

- 3,465 View

- 173 Download

-

Related articles in

J. Conserv. Sci.